TRICONEX 9662-910 Deploy devices at remote locations

The brand TRICONEX color standard applies industrial height 208mm rated current 416mA

Protection Level IP45 Suitable for motor power 163KW Application Area Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part No. 9662-910

Applicable pipe 2 Whether imported is weighing 3.65 kg can be sold nationwide

TRICONEX 9662-910 Deploy devices at remote locations

The industrial camera is generally installed on the machine line instead of the human eye to do measurement and judgment, through the digital image acquisition target converted into image signals, transmitted to the special image processing system, the image system on these signals for a variety of operations to extract the characteristics of the target, and then according to the results of discrimination to control the field equipment action. With the rapid development of the domestic machine vision industry, an important component of the machine vision system, industrial cameras have also been greatly developed. Digital industrial cameras have no limit on the size of the subject, and depending on the conditions of the lens, they can either photograph general substances or be used for microscope photography. At present, the main uses of industrial cameras include the following aspects: (1) in the development of products and verification of products, etc. : such as the development of metal materials and resin materials, used to observe the direction and state of internal cracks when the material is impacted, can be used to analyze the structure of the material when the material is destroyed, and industrial online detection of electronic products. (2) In the printing process of the packaging and labeling industry, subtle defects in high-speed printing can be detected in real time, so that measures can be taken to reduce losses. Common defects such as scratches, dust, omissions, ink marks, wrinkles, etc. can be detected, improving return on investment, reducing waste expenditure, and improving customer satisfaction and trust. (3) Other fields: such as machine vision, scientific research, military science, aerospace and many other fields, especially in the intelligent transportation industry: speeding capture, red light electronic police, high-speed intersections, buckle charges and other transportation industries have also been well used. Before the actual purchase and use of industrial cameras, the first thing that needs to be determined is the type of camera. Below is the classification of industrial cameras according to different industry standards. (1) The chip type is divided into CCD camera and CMOS camera; (2) The structural characteristics of the sensor are divided into linear array camera and planar array camera; (3) According to the scanning mode, it is divided into interlaced scanning camera and progressive scanning camera; (4) The resolution is divided into ordinary resolution cameras and high resolution cameras; (5) The output signal mode is divided into analog camera and digital camera; (6) Output color is divided into monochrome (black and white) camera, color camera; (7) The output signal speed is divided into ordinary speed camera and high-speed camera; (8) The response frequency range is divided into visible light (ordinary) cameras, infrared cameras, ultraviolet cameras, etc. Why do industrial cameras lose frames? Choosing the right camera is also an important part of the design of machine vision system, the choice of camera not only directly determines the resolution of the captured image, image quality, but also directly related to the operation mode of the entire system. Poorly designed drivers or industrial camera hardware can cause frame loss because the data channel is blocked and cannot be processed in a timely manner, so when a new image comes in, the previous one may be discarded, or the new image may be discarded. To solve this problem, designers need to carry out precise design for each link of driver and industrial camera hardware data transmission. Smart Cameras and Industrial cameras A Smart Camera is not a simple camera, but a highly integrated micro-miniature machine vision system. It integrates image acquisition, processing and communication functions in a single camera, providing a versatile, modular, highly reliable and easy to implement machine vision solution. At the same time, due to the application of the latest DSP, FPGA and mass storage technology, its degree of intelligence is continuously improved, which can meet the application needs of a variety of machine vision. Industrial camera and smart camera application is not much different, but there is a big difference in the use of industrial cameras need an external controller, the need for professional software personnel to program, can cope with a variety of complex detection requirements, and smart camera built-in simple and practical debugging tools, can work independently without the need for an external controller, simple operation, easy to get started. One of the strengths of ABB LGR analyzers is their stability and portability, two key features that explain why many customers use them for a variety of on-board operations. Many scientific research results of airborne flight monitoring of greenhouse gases have been published in papers written by some scientists.

TRICONEX 9662-910 Deploy devices at remote locations

TRICONEX 9662-910

TRICONEX 9668-110

TRICONEX 9753-1

TRICONEX 9760-210

TRICONEX 9761-210

TRICONEX 9765-210

TRICONEX 9771-210

TRICONEX 9792-610

TRICONEX 9853-610

TRICONEX 9860-610

TRICONEX AI6700

TRICONEX AIH 3723X

TRICONEX AO2481

TRICONEX D06603

TRICONEX DEMO

TRICONEX DI 3506X

TRICONEX DI6503

TRICONEX DO 3626X

TRICONEX DO2401

TRICONEX EPI3382

TRICONEX EPI3382 7400221

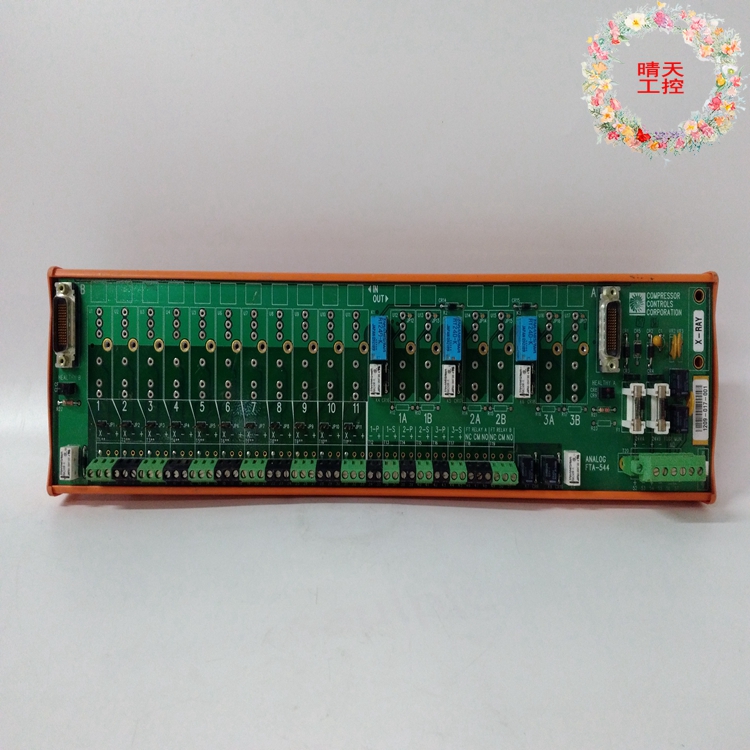

TRICONEX FTA-544

TRICONEX HCU3700/3703E

TRICONEX ICM6211

TRICONEX IMSS 4701X

TRICONEX JWA600-24