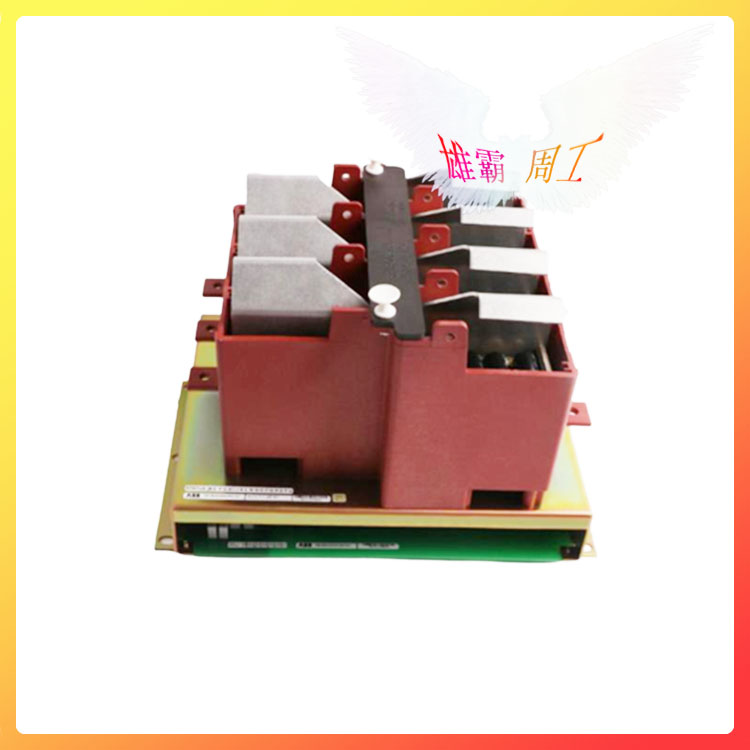

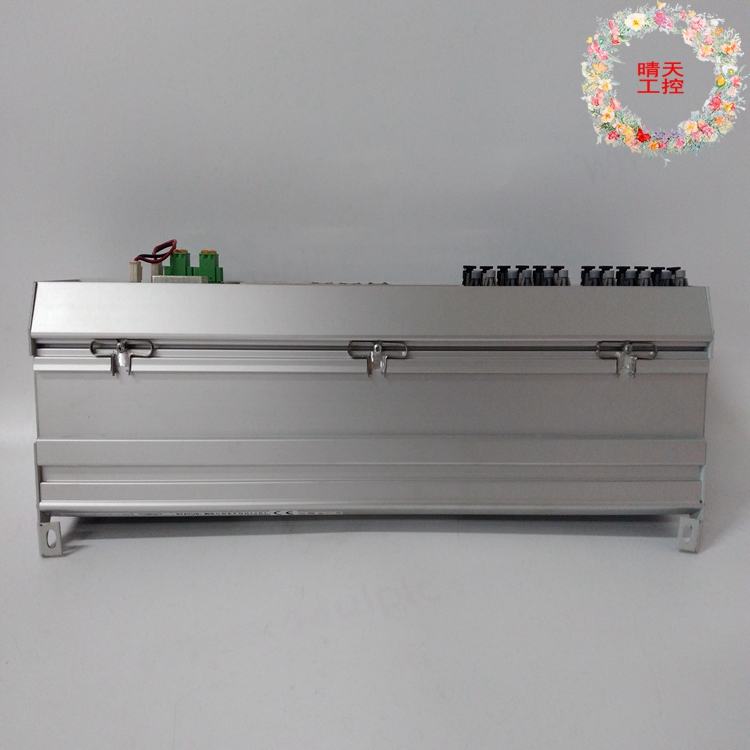

PPD113B01-10-150000 Order Number 3BHE023784R1023 CPU ABB module

Brand ABB color standard Application Industrial height 340mm rated current 215mA

Protection Level IP45 Suitable for motor power 90KW Applicable Site Power Industry BOM Number GJR2391500R1220 Power industry HIEE401782R0001 Part number PPD113B01-10-150000 3BHE023784R1023

Applicable pipe 2 Whether imported is weighing 8.66 kg can be sold nationwide

PPD113B01-10-150000 Order Number 3BHE023784R1023 CPU ABB module

The recommended operating temperature range for NI devices is 0 to 50 °C, the storage temperature range is -20 to 70 °C, and the non-condensing relative humidity range is 10 to 90%. It is designed to comply with IEC 61010-1, UL 3111-1 and CAN/CSA C22.2 No. 1010.1 for electrical measuring and testing equipment. National Instruments SCXI-1346 multi-chassis cable adapter

The SCXI-1346 (Part number: 776574-46) is suitable for applications involving multi-chassis SCXIS, as it can connect them to a single DAQ device. This cable adapter has two cable connections. One connection is used for signals from the digitizer or previous SCXI chassis, while the second connection is used to route the digitizer signal to subsequent chassis. SH68-68-EP (Part No. : 184749-01, 1 m cable; 184749-02, 2 m cable; 184749-05, 5 m cable; Or 184749-10, 10 m cable) can be purchased separately and with NI SCXI 1346. This cable adapter has a mounting bracket that reliably connects to the SCXI chassis.

PPD113-B03-23-111615 3BHE023584R2365 PPD113B03-26-100100 3BHE023584R2625 PPD113B03-26-100110 3BHE023584R2634 PPD113B01-10-150000 3BHE023784R1023 PPD512 A10-15000 3BHE040375R1023 SCXI 1346 has four connectors. The first connector is a 68-pin male connector on the front panel, printed To Next Chassis. The next connector is another 68-pin male connector on the front panel, printed From the DAQ Board or Previous Chassis. The third connector is a 50-pin cm wire connector on a printed circuit board. The last connector is also a 50-pin connector, but it is the bracket mounting female head on the back of the cable adapter.

With the NI SCXI 1346 in a multi-chassis system, the following items are required: One computer, one small flat-head screwdriver, 68-pin shielded cable, one 68-pin E-Series DAQ device, one SCXI 1001 or SCXI 1000 chassis (version K or later), one or more SCXI for each chassis Modules (except SCXI-1127, SCXI-1190, and SCXI-1191), SCXI 1349 Shielded Cable Assembly, and SCXI-1346 Installation Guide. Users should keep in mind that the total cable length used in a multi-chassis SCXI system should not exceed 10 m. This will help ensure reliable operation.

The SCXI 1346 runs with NI-DAQmx driver software that is compatible with the software package/Application development Environment (ADE), Examples include LabVIEW, LabWindows, LabVIEW SignalExpress, Measurement Studiio, Visual C++, or Visual Basic. Device hardware can be configured using the National Instruments Measurement & Automation Explorer (MAX) tool.

In the whole PLC control system, the most prone to failure in the site, the site is most prone to failure in the following aspects.

1, the first type of fault point is also the most fault location) in the relay, contactor

PPD512 A10-15000 3BHE040375R1023 PPD512 A10-15000 3BHE040375R1023 PPD512A10-150000 3BHE040375R1023PPD113B01-10-150000 3BHE023784R1023 IS420UCSBH4A PPD113B03-26-100110 3BHE023584R2634 PPD115A102 3BHE017628R0102

For example, in the daily maintenance of a production line PLC control system, the largest consumption of electrical spare parts is all kinds of relays or air switches. In addition to the quality of the product itself, it is mainly due to the poor on-site environment. For example, contactor contacts exposed to the production environment are easy to ignite or oxidize, and gradually heat up and deform until they cannot be used. All on-site control boxes in this production line are made of cabinets with better tightness, and the service life of its internal components is obviously longer than that of other components in open cabinets. Therefore, to avoid such failures, high-performance relays should be selected as far as possible, and the use environment of components can be improved, which can reduce the frequency of replacement and reduce the impact on the operation of the system.

2. The second type of failure occurs on equipment such as valves or RAMS

Because the relative displacement of the actuator of this kind of equipment is large; Or the transmission structure is complex, mechanical, electrical, hydraulic and other links are slightly not in place will produce errors or failures. In the long-term operation state, if the lack of operation and maintenance, easy to cause the valve body parts card, plugging, leakage and other phenomena. Therefore, when the system is running, it is necessary to strengthen the inspection of such equipment and deal with problems in time. Our factory has established a strict point inspection system for such equipment, regularly checking whether the valve is deformed, whether the actuator is flexible and available, whether the controller is effective, etc., which well ensures the effectiveness of the entire control system.

3, the third type of failure point may occur in switches, limit positions, safety protection and field operation on some components or equipment

The reason may be because of long-term wear and tear, or it may be rust and aging after long-term use. For example, the cloth walking car on the kiln tail ball storage of the production line moves back and forth frequently, and the on-site dust is large, so the contact of the close switch appears deformation, oxidation, dust blockage, etc., resulting in bad contact or insensitive mechanism action. The troubleshooting of such equipment faults is mainly reflected in regular maintenance to keep the equipment in good condition at all times. For limit switches, especially limit switches on heavy equipment, in addition to regular maintenance, multiple protective measures should be added in the design process.

PPD113B01-10-150000 Order Number 3BHE023784R1023 CPU ABB module

ABB 3HAC10847-1

ABB 3HAC17484-8108

ABB 3HAC5497-1

ABB 3HAC5498-1

ABB 3HAC5518-1

ABB 3HAC5566-1

ABB 3HAC6157-1

ABB 3HAC6428-1/04

ABB 3HAC7344-1

ABB 3HAC7681-1

ABB 3HAC9710-1

ABB 5360673-01

ABB 57160001-KX

ABB 5SDD1060F0001

ABB 5SDF0860H0003