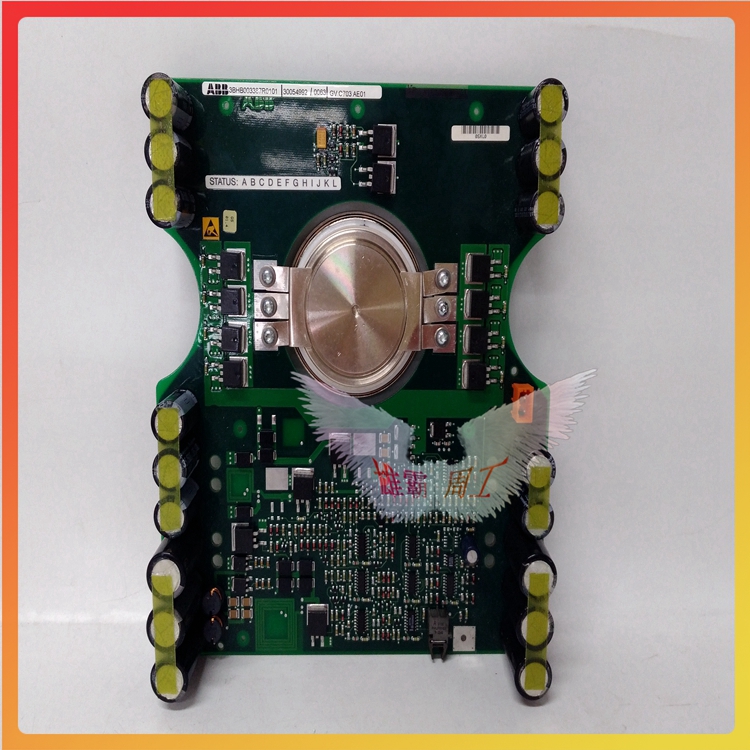

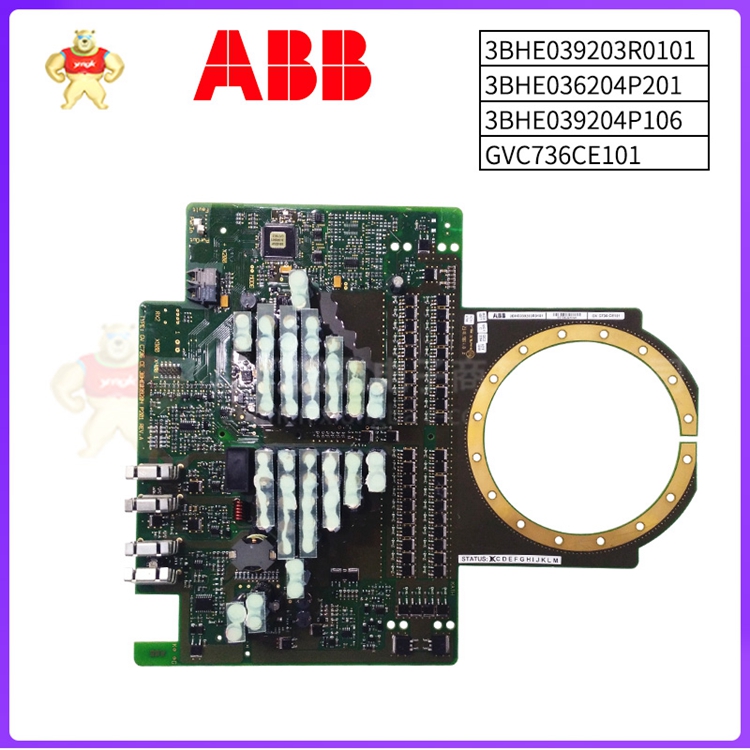

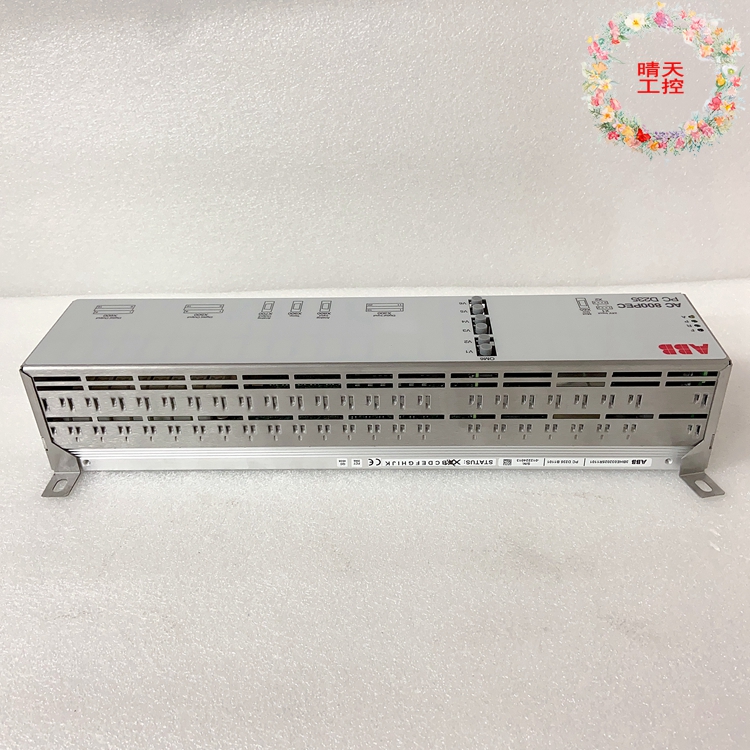

PCD235B1101 3BHE032025R1101 ABB input coupling unit ICU static excitation system

Brand ABB color standard Application Industrial height 138mm rated current 260mA

Protection Level IP45 Suitable for motor power 229KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part Number PCD235B1101 3BHE032025R1101

Applicable pipe 2 Whether imported is weighing 2.69 kg can be sold nationwide

PCD235B1101 3BHE032025R1101 ABB input coupling unit ICU static excitation system

PCD235B1101 3BHE032025R1101 field bus system can make many field equipment (such as PLC, intelligent transmitter, inverter) in the same bus for bidirectional multi-information digital communication, so it can be convenient to use different manufacturers of control and measurement systems to connect to each other into a communication network. Jinan Bade color Plate Co., Ltd. is a large color plate production base with an annual output of 200,000 tons invested by Jinan Iron and Steel Group Corporation in 2003. The curing furnace, thermal oil furnace and gas hydrogen production system in the production line must be pressurized twice through the gas compressor to meet the production process requirements

With Profibus-DP process fieldbus communication technology, the automation control unit and inverter are made of different manufacturers, respectively using Siemens S7-300 PLC and ABB ACS600 inverter.

2 System configuration and communication protocol

(1) System configuration

PCD235B1101 3BHE032025R1101 The system to Siemens and ABB related products to achieve the full digital AC speed control system in Profibus-DP network communication and control principle. The attached figure is the network configuration diagram of the Profibus-DP network of the system, in which PLC is SIMATIC S7-315-2DP of Siemens, frequency converter is ACS600 series, and NPBA-12 is the communication adapter supporting the frequency converter. The programming software is STEP7 V5.2 software, which is used to program S7-300 PLC and configure Profibus-DP network and communication. The upper computer screen operation adopts WinCC5.1 screen programming and operation, and the communication with PLC adopts Ethernet communication mode.

(2) Communication protocol

In this system, when the S7-300 PLC is the master station and the inverter is the slave station, the master station transmits the operation instruction to the inverter, and receives the feedback signal of the operation state and fault alarm state of the inverter. The frequency converter is connected with the NPBA-12 communication adapter module, and is connected to the Profibus-DP network as a slave station, and receives the control from the master station SIMATIC S7-315-2DP. The NPBA-12 communication adapter module will receive the process data from the Profibus-DP network into the bidirectional RAM, each word is addressed, the bidirectional RAM at the converter end can be sorted by the addressed parameters, write to the converter control word, set value or read the actual value, diagnostic information and other parameters.

PCD235B1101 3BHE032025R1101 frequency converter fieldbus control system from the software point of view, its core content is the fieldbus communication protocol. The data telegraph structure of Profibus-DP communication protocol is divided into protocol header, network data and protocol layer. Network data is PPO including parameter value PKW and process data PZD. Parameter value PKW is some function codes to be defined when the inverter is running. Process data PZD is some data values to be input/output during the operation of the inverter, such as frequency given value, speed feedback value, current feedback value, etc. Profibus-DP has two types of Ppos: one is PZD without PKW and has 2 or 6 words; The other type is PZD with PKW and also 2, 6, or 10 words. The purpose of classifying the network data in this way is to complete different tasks, that is, the transmission of PKW and the transmission of PZD do not affect each other, and they work independently, so that the inverter can operate in accordance with the instructions of the upper level of automation system.

3 STEP7 Project system configuration and communication programming

(1) Use the STEP7V5.2 configuration software to enter the Hardware Configure to complete the S7-300 PLC hardware configuration;

(2) PCD235B1101 3BHE032025R1101 Select S7-315-2DP as the master station system, import the GSD (Device database) file of NPBA-12 into the programming environment of STEP7, and configure the software NPBA-12 onto the DP network of S7-315-2DP as the master station. And select the use of PPO type, this design uses PPO4, set the site network address. In the structure of the variable frequency drive Profibus, ABB drives use the PROFIBUS-DP communication module (NPBA-12) for data transmission, which is mainly periodic: The host reads the input information from the slave station and sends the output information back to the slave station, so it is necessary to call two system function blocks SFC14 and SFC15 in the PLC main program to read and write these data and realize the communication control to the inverter.

PCD235B1101 3BHE032025R1101 ABB input coupling unit ICU static excitation system

ABB SE96920414 YPK112A

ABB SNAT617CHC

ABB SPA-ZC22

ABB SPAD346C

ABB SPCJ4D34-AA

ABB TA524

ABB TB521-ETH

ABB TC625

ABB TC630

ABB TET106 11355-0-6050000

ABB TK516

ABB TU515

ABB TU804-1

ABB TU810V1