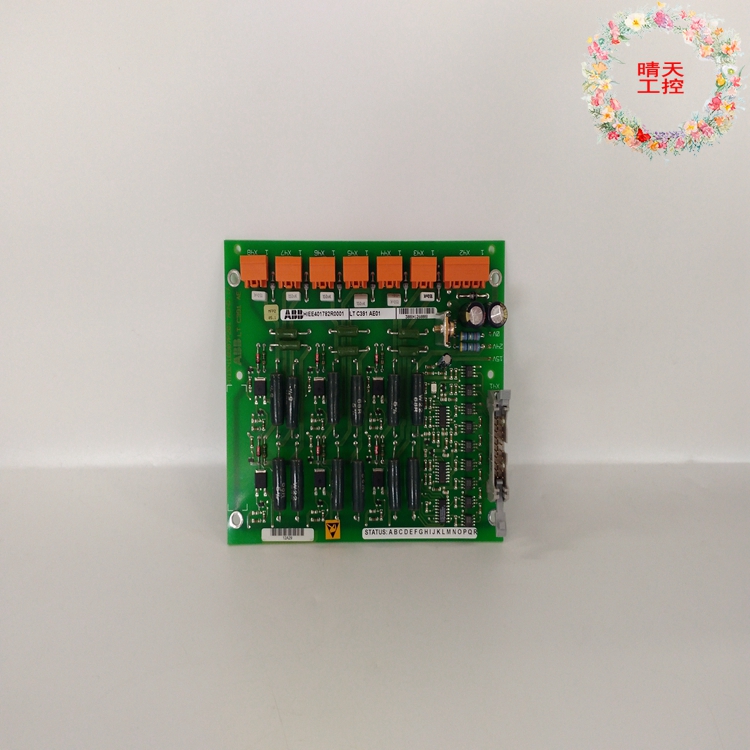

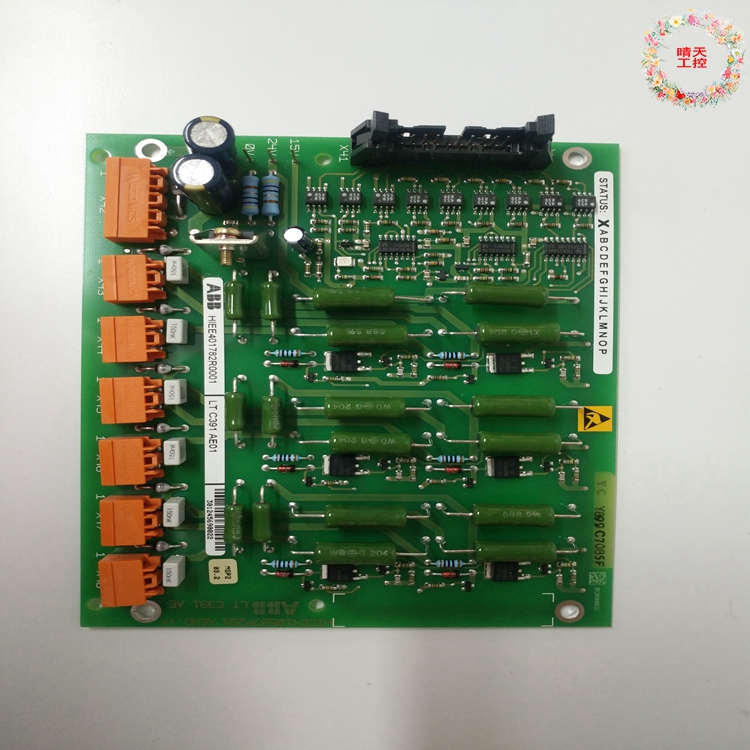

HIEE401807R0001 ABB 800xA control system power supply device industrial control card

Brand ABB color Standard Application Industrial height 268mm rated current 150mA

Protection Level IP45 Suitable for motor power 259KW Applicable Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part number HIEE401807R0001

Applicable pipe 2 Whether imported is weighing 3.68 kg can be sold nationwide

HIEE401807R0001 ABB 800xA control system power supply device industrial control card

automate

Automation has four dimensions: height, width, depth, and time. When the device must precisely place the object in a specific location, it needs to perform motion control, that is, control position, speed and acceleration. Precision and reliability of motion control are more important than any other factor in the manufacture of specialized products.

When digital information is translated into precise physical motion, previously unfeasible applications suddenly become possible. This further strengthens the promotion of Industry 4.0 in applications such as advanced robotics, Internet of Things (IoT) and Industrial Internet of Things (IIoT), battery-powered medical devices, additive manufacturing and prosthetics. Each of these applications requires a high level of control precision in the manufacturing equipment.

Therefore, for these applications, translating digital information into physical motion and accurately placing parts requires more than just transferring data to the motion control system. In the following sections, we discuss precision motion control, introduce medical and industrial automation application requirements, and highlight high-performance Trinamic products in each area.

Precision motion control

Precision motion control uses stepper motors to guide the placement of active machine components. The open-loop system uses a stepper motor to convert the electronic control signal into the precise rotation position of the shaft. For more precise applications, the engineers added an inspection function to measure the position of the shaft. The measuring device sends dimensional data back to the controller for comparison with the set value, enabling differential correction.

This two-way communication is called a closed loop. CNC machining is one of the most well-known applications benefiting from advanced precision motion control, but 3D printing and desktop manufacturing also benefit from more precise control. Inspection equipment, pickers and automated assembly lines that feed information back to the controller are three other areas that benefit from high-precision motion control. With precise motion control, the lab runs much more smoothly and the warehouse is much more efficient. At the same time, this motion control also reduces product costs due to inefficiency, including:

Heat loss and power consumption resonant audible noise sensorless diagnosis of battery life

The Trinamic motion control architecture consists of multiple functional blocks. The motor controller (or motion controller) receives commands through a selected interface in a specified protocol. These commands are converted into signals for motor control and drive components. To facilitate integration into the application’s firmware, the code is exported in Trinamic format or C. Read on to learn about Triminic’s products for medical and industrial automation applications.

High precision application

Trinamic develops products that address performance issues in medical and industrial automation.

Medical treatment

Medical devices, such as pumps and ophthalmic equipment, require precise control at low speeds. Applications ranging from tissue analysis to blood centrifugation and fluid handling offer opportunities to address accuracy at low speeds and with minimal vibration. The current circuit provided by Trinamic technology is a near-perfect sine wave to solve the problem of excessive vibration. These smooth curves limit vibrations that can affect tolerances. Low current conversion efficiency in the motor can cause the temperature of the components to rise, causing system failure or automatic shutdown events. In addition, adjusting the acceleration curve allows system operators to improve accuracy and make the movement of machine components smoother.

Several Trinamic products for medical applications are recommended below:

Tissue Analysis: TMCM-3110 (3-axis, for sensorless load dependent current control)

High reliability: Blood centrifugation: TMCM-1636 (single axis, for 3-phase BLDC motors)

Low latency: Liquid handling: TMCM-6110 (6-axis, for sensorless load dependent current control).

Ensuring accurate, low speed and smooth operation is the key to motion control in medical equipment automation. With a range of solutions ranging from complex chips to smart motors, Trinamic’s motion control solutions are customizable and can be flexibly applied in the medical field.

industry

Production efficiency and capacity drive product development for industrial applications. Along with improvements in motion control, Trinamic’s advanced diagnostics and interconnect drives help enable the smart factory. The technology is now powerful enough to be used for standalone applications as well as for networking. By making individual modules, system designers can tailor efficient solutions to their needs. 3D printing, robotics and factory automation are three applications that require precision automation. Trinamic products suitable for these applications include:

3D printing: TMC2209 (ultra-quiet motor drive integrated circuit for 2-phase stepper motors) Robot: TMC5160 (high-power stepper motor controller)

Factory Automation: TMC262 (Integrated Stepper Motor)

These products address major challenges in industrial applications. 3D printing is notoriously noisy and can interfere with other activities near the job site. The TMC2209 achieves smooth sine waves, enabling the quiet fabrication of parts with higher dimensional accuracy. The TMC5160 is also soft, enabling rapid production of high-precision robotic components. It is highly integrated and scalable, maximizing operational efficiency to drive capacity without wasting energy and time. The TMC262 can drive a 40mA gate current, making it ideal for laboratory and factory automation applications

Precision control has transformed two key macro industries – medical and industrial automation. Precise motion control is a booster for both industries. It improves vibration resistance, energy efficiency, noise and smoothness of motion, and significantly reduces tolerances for automated motion to increase its accuracy.

Industrial automation is driving the development of Industry 4.0, bringing smart manufacturing technology to the market. Adding precision motion control can free up the productivity of 3D printing, CNC machining, picking machines, inspection, quality control, test equipment, automated assembly lines and conveyor belts, and collaborative robots. To help the factory’s supply chain and operations, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) have increased productivity, accelerated time-to-market and achieved near-on-time product flow.

HIEE401807R0001 ABB 800xA control system power supply device industrial control card

ABB 07AC91D

ABB 07BR61R1 GJV3074376R1

ABB 07CR41

ABB 07DC91C

ABB 07EA90-SI

ABB 07KR51 220VDC

ABB 086339-001

ABB 086349-002

ABB 086406-002

ABB 086407-502

ABB 128877-103

ABB 1TGB302003R0003

ABB 1TGE120011R1001

ABB 216AB61

ABB 216DB61

ABB 216DB61 HESG324063R100/J

ABB 216EA61b

ABB 216EA62 1MRB150083R1/F 1MRB178066R1/F