FOXBORO-DLM01 Excitation controller of ABB servo drive system

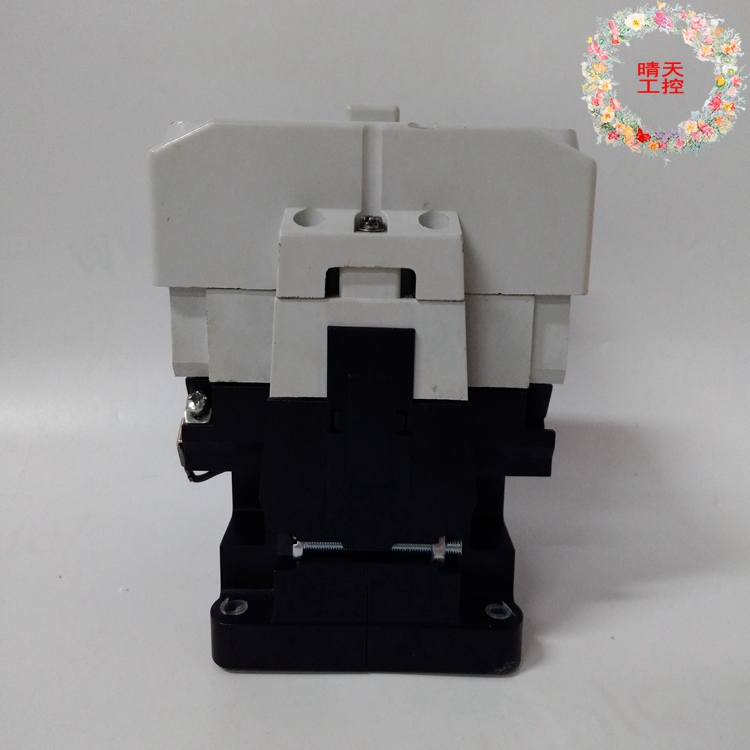

Brand ABB Color Standard Application Industrial height 127mm rated current 455mA

Protection Level IP45 Suitable for motor power 345KW Application Site Power Industry BOM Number GJR2391500R1220 Power industry HIEE401782R0001 Part Number DLM01

Applicable pipe 2 Whether imported is weighing 4.22 kg can be sold nationwide

FOXBORO-DLM01 Excitation controller of ABB servo drive system

Test method for DMP-01 of Hengtaida leak-blocking simulator

Test equipment

a) Drying oven: temperature control sensitivity ±3℃; b) Vibrating screen: GS-86 or similar;

c) Hengtaida plugging simulator; DLM-01 type, temperature control range is room temperature ~ 150℃, pressure fan

The circumference ranges from 0 MPa to 7MPa. Crack type template:

— Hengtaida leakage simulation device straight seam template: thickness 10mm; Seam length 40mm; The seam width is 1mm, 2mm, 3mm, 4mm, 5mm.

— Hengtaida leakage simulation device vertical seam template; The thickness is 5mm; Seam height 50mm; The seam width is 1mm, 2mm, 3mm: 4mm, 5mm. Hole type template

— Hengtaida single hole template for plugging simulator; Thickness 10mm; The aperture is 1mm, 2mm, 3mm, 4mm, 5mm.

— Porous template of Hengtaida leakage simulation device: 59 holes; The thickness is 5mm; The aperture is 1mm, 2mm, 3mm, 4mm respectively. Sand bed: Quartz sand particle size is adjustable, filter area is 2289mm², sand bed thickness is 35mm. 3.1.2 Test instruments

a) Electronic balance: index value 0.01g;

b) Standard screen: aperture 4mm, 2mm, 0.9mm, 0.6mm, 0.45mm, 0.28mm; c) Direct-reading viscometers: Fann35 or similar products;

d) Electric mixer; D90 or similar products, speed 0r/min ~ 3000r/min; e) weighing bottle; Phi 70 mm x 30 mm; f) Magnetic stirrer;

g) Dryer: medium 200mm, silica gel desiccant: h) stopwatch; i) Beaker: 150mL; j) Measuring cylinder: 50mL, 100mL; k) fluorine gas source; The pressure is not less than 10MPa;

Plugging test procedure

Preparation of base pulp for test purposes

5L of base paste was prepared by adding 50.0g drilling bentonite into 100mL of distilled water. The base paste was stirred with an electric mixer for 4h at a rotating speed of 1000r/min~150Or/min, and then cured at room temperature for 24h for use. The apparent viscosity of the base paste should be in the range of 15mPa·s~25mPa·s, otherwise reformulated.

Preparation of test plugging slurry

Add a certain proportion of bridging plugging material to the base slurry after curing for 24h while stirring, and stir on an electric mixer for 30min to prepare plugging slurry.

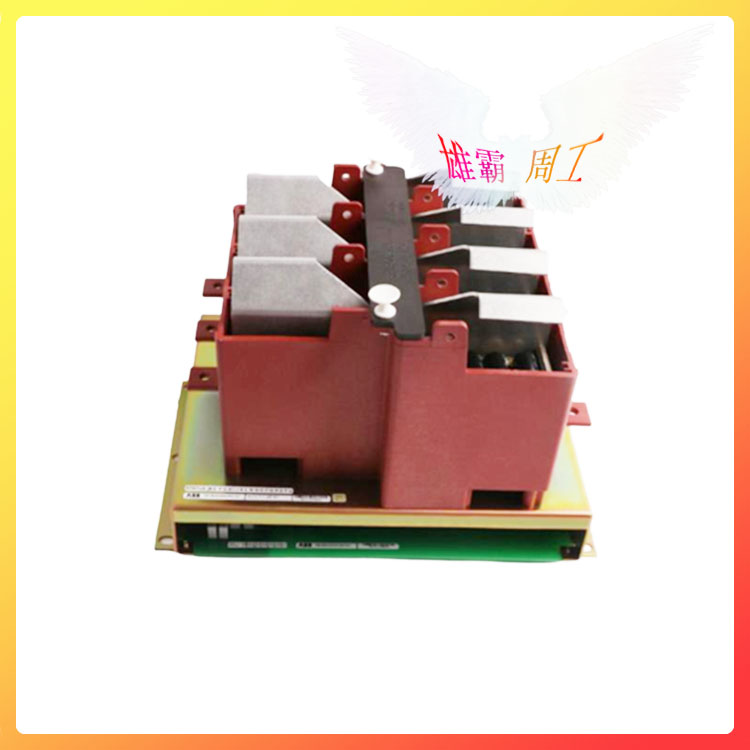

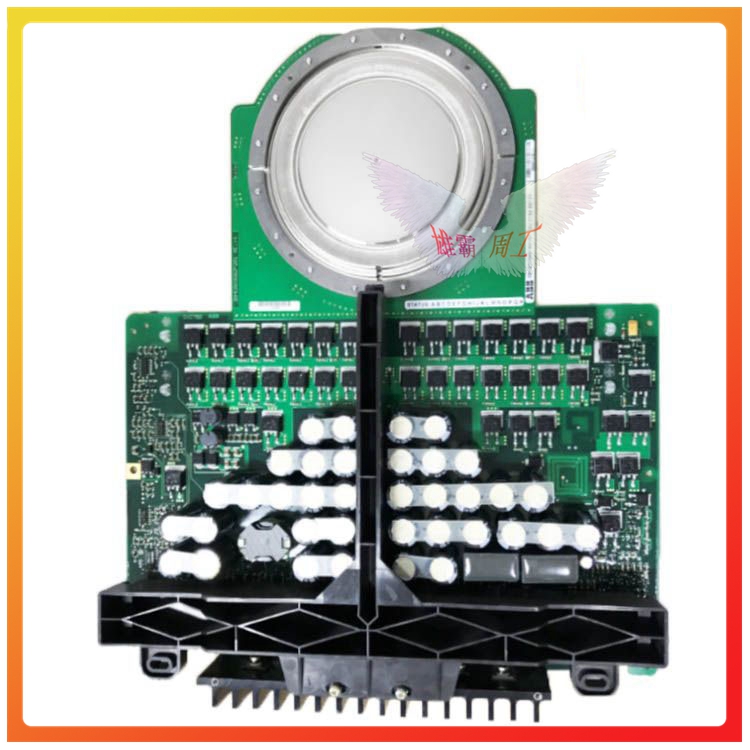

FOXBORO-DLM01 Excitation controller of ABB servo drive system

ABB DSQC346G

ABB DSQC346U

ABB DSQC352

ABB DSQC354

ABB DSQC602

ABB DSQC608

ABB DSQC609

ABB DSQC626

ABB DSQC627 3HAC020466-001

ABB DSTD108

ABB DSU10

ABB DSU14

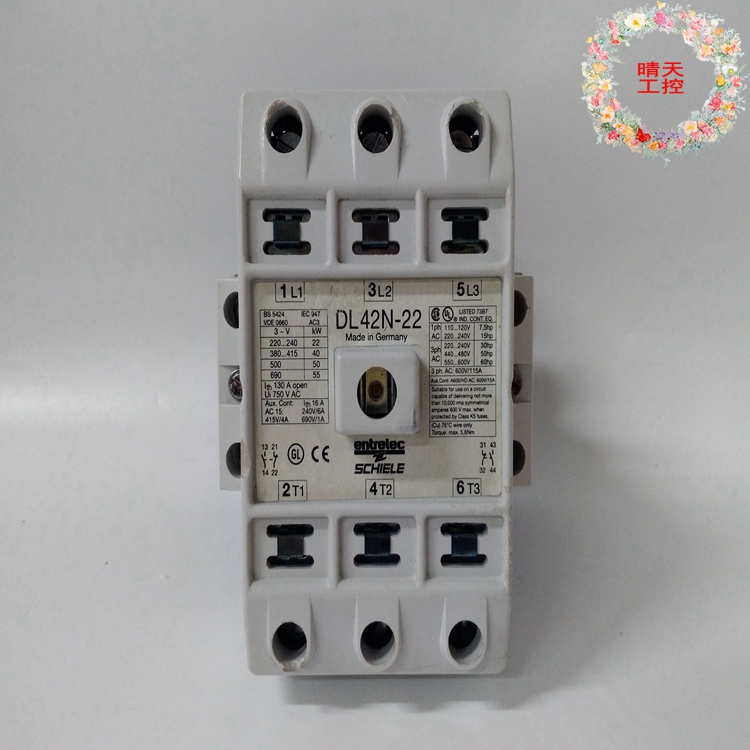

ABB EHDB130

ABB EHDB280

ABB IMFEC12

ABB IMMFP12

ABB IMMPI01

ABB IMSED01

ABB IMSET01

ABB INNIS01

ABB INSEM01

ABB M2004HW

ABB MSR04XI

ABB NTAC-02

ABB P-HA-RPS-32200000

ABB PM630

ABB PM632