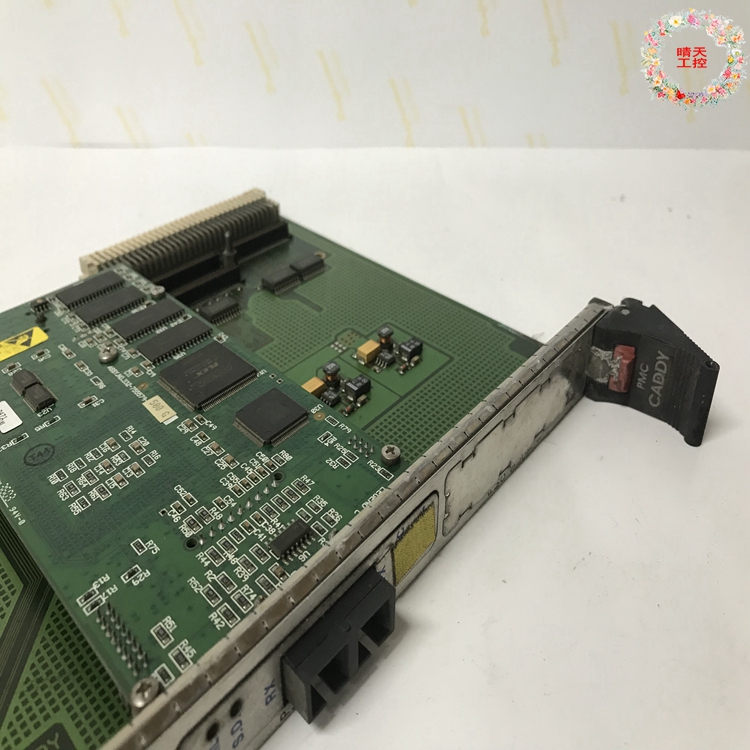

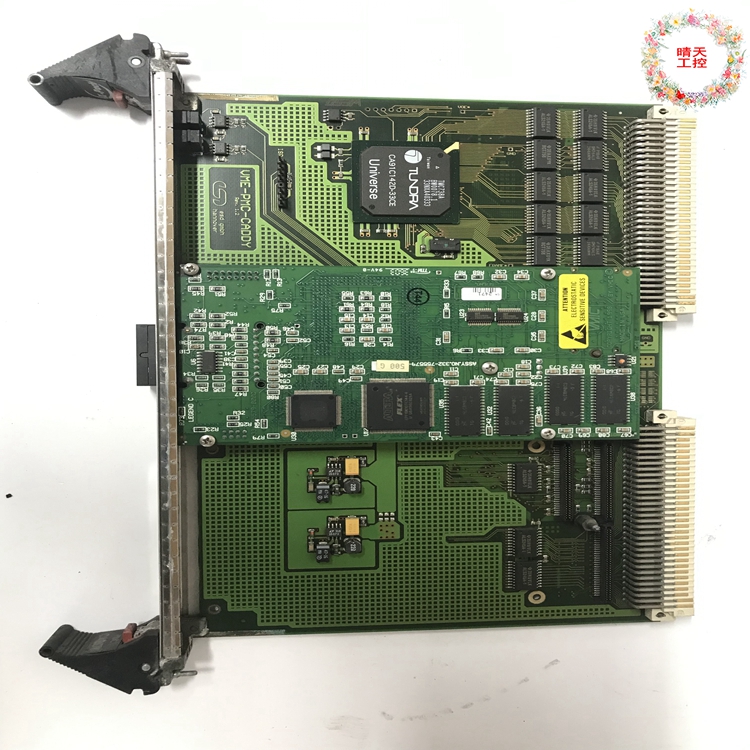

ABB PM820-2 module controller

Brand ABB color standard application Industrial height 166mm rated current 268mA

Protection Level IP45 Suitable for motor power 268KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part No. PM820-2

Applicable pipe 2 Whether imported is weighing 2.86 kg can be sold nationwide

ABB PM820-2 module controller

ABB’s ACS350 Universal mechanical drive has been designed and built so that volume machine manufacturers can easily increase average throughput time by averaging two seconds of programming time per unit. ABB has just increased the power rating of the inverter to 15 HP (480 volts). These units are ideal for a variety of mechanical applications in the food processing, material handling, HVAC (pumps and fans), textile, printing, rubber and plastics, and woodworking industries. Michael Mikolajczak, product line manager for the ACS350 drive family, said: “The existing R3 rack drive has more horsepower, can replicate the parameter set of the individual units extremely quickly, and is competitive.” The R0-R3 frame drive also supports simple, repeatable mounting, he said, with uniform height and depth across the horsepower range. “As the horsepower increases, the difference is that the drive gets slightly wider,” he noted. The features included in ABB’s extended ACS350 Universal Mechanical drive family are designed to minimize installation and commissioning time and include:

FlashDrop technology;

Eight (8) state sequence programming (similar to PLC function);

Flexible user interface;

High-speed communication; and

The cabinet is compatible with hardware. Download and upload parameters with the new FlashDrop (Model MFDT-01) – No need to power the drive The FlashDrop technology acquired by ABB makes parameter selection and setting as easy as operating a TV remote control. With the handheld FlashDrop MFDT-01 device, important parameters can be downloaded and uploaded to a “no power” drive in less than three (3) seconds. The device can store up to 20 different sets of machine parameters, and for greater convenience, each set of parameters can be named to clearly show the relevant end user or application. A particularly useful feature is that parameter setting is done “flash in” without the need to connect the power to the drive; In fact, you don’t even need to completely unpack the drive. “It also makes it easy for distributors to pre-configure drives before delivery and helps streamline the commissioning process for high-volume Oems,” Mikolajczak said. FlashDrop allows for custom menu structures. You can set and hide parameters and change the appearance of menus to speed up setup and configuration. It also enables users to easily copy parameters between drives: simply upload them to a FlashDrop unit and download them to a drive. FlashDrop devices can be connected to a PC for additional storage capacity, and parameter sets can also be created or edited using the DrivePM (Parameter Manager) PC interface. FlashDrop is quick and easy to use and requires no driver knowledge. You can also create or edit parameter sets using the DrivePM (Parameter Manager) PC interface. FlashDrop is quick and easy to use and requires no driver knowledge. You can also create or edit parameter sets using the DrivePM (Parameter Manager) PC interface. FlashDrop is quick and easy to use and requires no driver knowledge. Eight-state sequential programming (PLC-like functionality) Sequential programming is a standard feature of ABB Universal Mechanical drives and provides an easy way to create a preset sequence of operations without any drive options. These PLC-like programs are sufficient for many basic applications where drivers control motors using signals from sensors and limit switches. This helps reduce external PLC capacity requirements, which simplifies the complexity of the motor control system and reduces other programming features including speed compensated stop and programmable delay stop – ideal for material handling applications that need to be stopped without being affected by changes in processing speed. Flexible user interface The user interface of universal mechanical drives is also designed to provide users with greater flexibility as well as the possibility of cutbacks. The control panel is only required for debugging or troubleshooting, and is not included in the frequency converter standard. Users who need panels can choose between two types: Basic and Assistant. Both are detachable, so the end user gets a panel to swap and use between multiple drives. Cabinet compatible hardware drivers equipped with EMC filters and built-in brake choppers are configured very simultaneously, and these drivers are very compact: at over 1 HP, the 480 V drives are the smallest in their class. Only the width of the drive increases with power, which facilitates easy installation into a cabinet or stand-alone configuration. The cable tunnel can be arranged in a straight line, and all screw holes can be drilled in a straight line. The 15 HP 480V unit uses the same standard R3 framework. DIN rail mounting for 15 HP units is also available, and the drivers can be mounted side-by-side without an air gap. When the cabinet depth is very high, the drive can even be mounted on one side of the back of the cabinet. The 15 HP version weighs just 5.5 pounds and the equipment is very simple to move and install. High-speed communication and control connections The driver has control connections: there are two bipolar analog inputs and five digital inputs (one of which can be configured as a pulse train), as well as an analog output, a relay output and a digital output. The driver uses a first-generation fieldbus with a small enclosed plug-in adapter to provide high-speed communication. ABB’s universal mechanical drives offer single-phase (240 V) power ratings up to 3 HP; Three-phase (240 V) 5 HP; Three-phase (480 V) up to 15 HP. Later in 2007, these drives will also be expanded to 25 HP (480V) and 10 HP (240V) with the new R4 rack size. ABB, Automation products, low voltage drives, is the world’s leading manufacturer of electric motors and drives. In the United States, a comprehensive channel of sales representatives, distributors and system integrators enables ABB, New Berlin, Wis., to offer a full line of energy-efficient power drives, motors and engineered drive systems to industrial and commercial customers. The products manufactured include AC and DC variable speed drives for motors from 1/8 to 135,000 HP, as well as application-specific drive system solutions for different customer needs.

ABB PM820-2 module controller

ABB 3HAB9271-1/01B

ABB 3HAC026271-001/DSQC646

ABB 3HAC031683-004

ABB 3HAC0977-1

ABB 3HAC10847-1

ABB 3HAC17484-8108

ABB 3HAC5497-1

ABB 3HAC5498-1

ABB 3HAC5518-1

ABB 3HAC5566-1

ABB 3HAC6157-1

ABB 3HAC6428-1/04

ABB 3HAC7344-1

ABB 3HAC7681-1

ABB 3HAC9710-1

ABB 5360673-01

ABB 57160001-KX

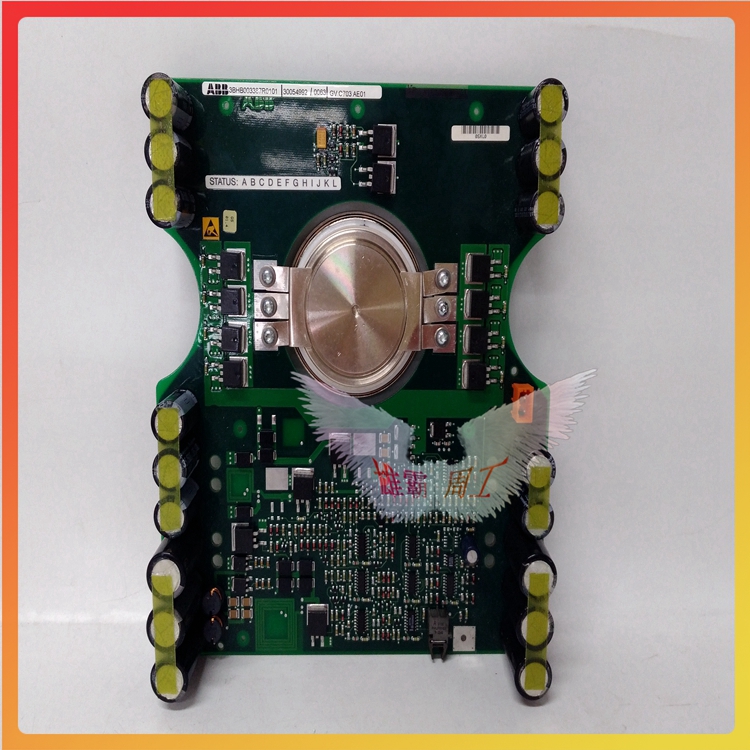

ABB 5SDD1060F0001

ABB 5SDF0860H0003

ABB 5SGY3545L0003