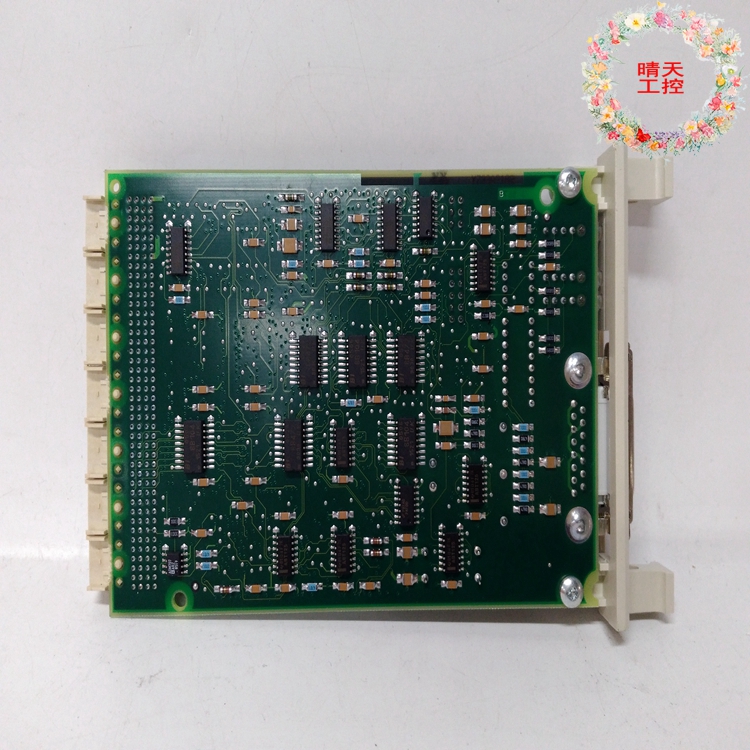

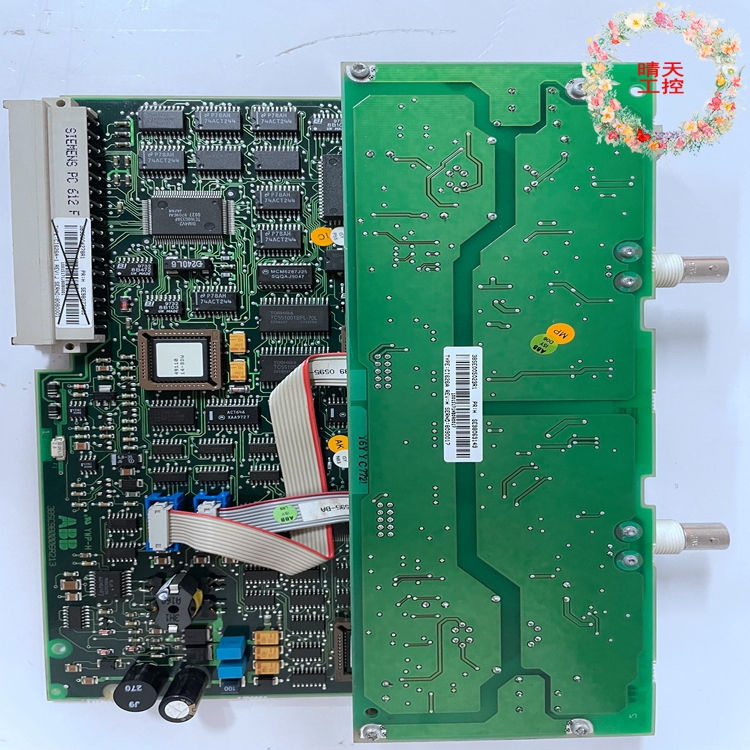

ABB module spot controller parts inventory 61615-0-1200000

Brand ABB Color Standard Application Industrial height 396mm rated current 579mA

Protection Level IP45 Suitable for motor power 119KW Applicable Site Power Industry BOM Number GJR2391500R1220 Power industry HIEE401782R0001 Part number 61615-0-1200000

Applicable pipe 2 Whether imported is weighing 6.28 kg can be sold nationwide

-1.jpg)

ABB module spot controller parts inventory 61615-0-1200000

Process control and communication control Siemens is the strong point, Siemens analog module is cheap, the program is simple, and Mitsubishi analog module is expensive, the program is complex, Siemens communication is also easy, the program is simple, Mitsubishi is weak in this function. Therefore, for different equipment and different control methods, we should reasonably choose PLC, use its strengths and avoid its weaknesses. For example, a device is only some action control, such as a manipulator, you can choose Mitsubishi PLC, a device has servo or step to position control, you can also choose Mitsubishi PLC; Like central air conditioning, sewage treatment, temperature control and so on, there are a lot of analog quantities to deal with, it is more appropriate to choose Siemens PLC, a lot of instrument data on the site to be collected by communication, choose Siemens good control. The chips are definitely different (in terms of capacity and speed) but the biggest difference is in the way the software is programmed and structured

I personally believe that the software of Mitsubishi PLC is at least 5 years behind that of Siemens. Large and medium-sized for the time being, take the advantage of Mitsubishi’s minicompanies FX series and Siemens S7-200 series contrast

1. Mitsubishi’s programming software from the early FXGPWIN to the recent GX8.0(the latest one I know), like all Japanese brands, the programming idea of this software is a top-down single vertical structure, while Siemens’ MicroWIN is both vertical and horizontal structure, and the subroutine supports local variables. The same function only needs to be programmed once, which greatly reduces the difficulty and time of development.

2, S7-200 has always supported a strong floating point operation, programming software directly supports the decimal point input and output, and Mitsubishi until the FX3U series launched in recent years to have this function, the floating point function of the previous FX2N series is fake.

3, the S7-200 analog input and output program is very simple and convenient, AD, DA values can be directly accessed without programming, Mitsubishi FX2N and its previous series require very cumbersome FROMTO instructions. FX3U now supports this feature, but five years or more later.

4, CPU226 and CPU224XP, the standard configuration of two 485 ports that is PPI port, the maximum communication speed of 187.5K, Mitsubishi FX3U before all series are a poor 422 ports, and the speed is 9.6K. If you need to connect a smart instrument, you must buy special modules such as FX2N0-485BD.

5, CPU226 program capacity 20K, data capacity 14K,FX2N a total of 8K. The later 3U was an improvement

But Mitsubishi’s FX2N series has two advantages, one is that the high-speed counter instruction is more convenient than the S7-200. The second is 422 more than the Siemens PPI mouth (because the 200 series PPI mouth is non-photoelectric isolation, non-standard operation and

The recently introduced S7-1200 series from Siemens directly supports Ethernet interfaces, and thanks to the integration of counting and measurement, closed-loop control, and motion control processes, the FX3U is once again far exceeded by Siemens by the above comparison of just minicommitters. As for the Siemens 300 and 400 series and the larger TDC series, there is no need to say more here, in a word, who uses who knows. Siemens’ PCS7 software is absolutely extensive and profound, and all Japanese brands can only look behind it.

Learning PLC, Mitsubishi is very easy to get started, because straight thinking is simple. From a learning point of view, Siemens is definitely better. Still the same sentence, using PCS7, just know that the Japanese software is junk.

There are also two communication ports of Siemens PLC, Mitsubishi has one, the two communication ports can be connected to download a data line and a touch screen to debug the program, otherwise you have to unplug the touch screen data line and then connect the touch screen data line to adjust the program is very troublesome.

ABB module spot controller parts inventory 61615-0-1200000

ABB CI810B

ABB DCP02

ABB DCP10

ABB DDI03

ABB DDO02

ABB DI610

ABB DI620

ABB DI810

ABB DI814

ABB DLM01

ABB DO610

ABB DO630

ABB DPW01

ABB DRA02

ABB DSAI146

ABB DSAO110

ABB DSBB175

ABB DSDP170

ABB DSDX404

ABB DSIH72VP ENOK

ABB DSPC170

ABB DSPC172

ABB DSPC172H

ABB DSPC406

ABB DSQC202

ABB DSQC313

ABB DSQC322

ABB DSQC327A

ABB DSQC346G

-1.jpg)

-1-100x100.jpg)

-1-100x100.jpg)