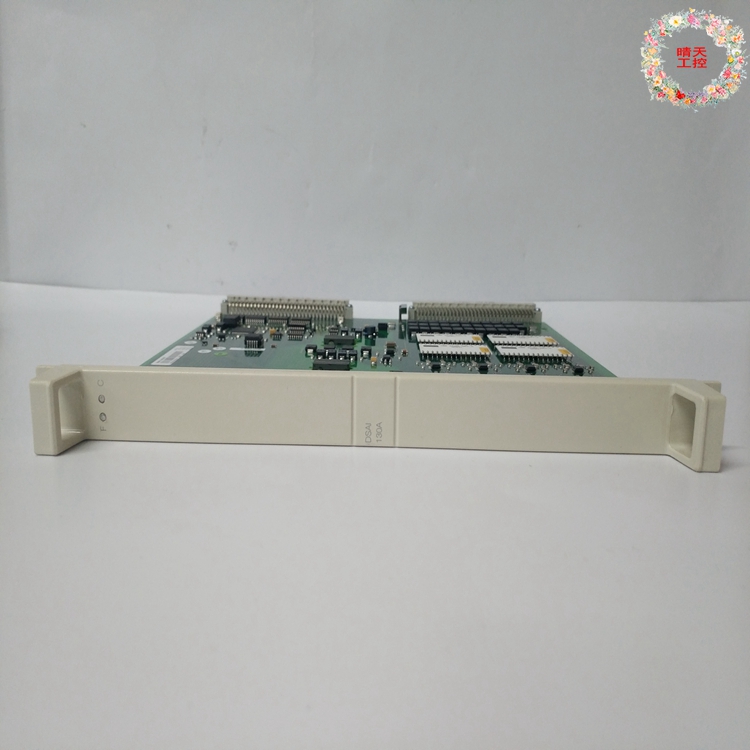

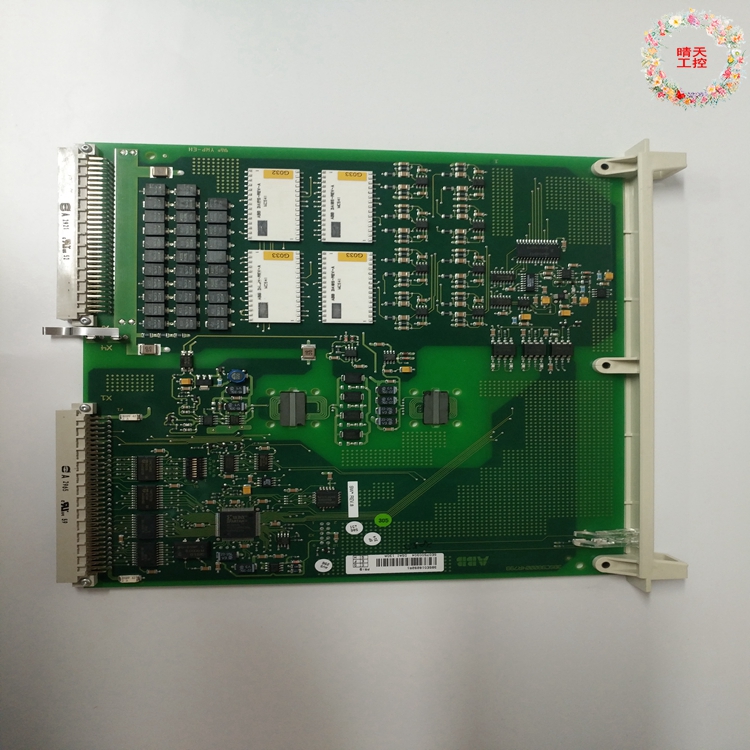

ABB DSDX404 automation processor module

Brand ABB color standard Application Industrial height 387mm rated current 565mA

Protection Level IP45 Suitable for motor power 319KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part number DSDX404

Applicable pipe 2 Whether imported is weighing 4.22 kg can be sold nationwide

ABB DSDX404 automation processor module

In the process of doing the whole win-making plan, we also constantly encounter problems and solve problems. But we don’t think that difficulty is a difficult thing, it is a process of exploring opportunities and innovation. Specifically, in the first quarter of the winning plan scenario mining problem, Schneider Electric first verified the external ecological richness to solve the whole problem, and this method also produced a very good positive effect on its internal recognition of open innovation. “By the second season, we were thinking about how to make it broadly replicable. First of all, we will focus on the customer’s program research, scenario analysis, discussion and prediction, and finally through the selection mechanism to screen out specific joint venture program scenario Electric transportation field is an important contributor and promoter of high-quality sustainable development. With the development of technology, the realization of electrification and intelligence in the transportation field will contribute to carbon reduction and low carbon. Take rail transportation as an example, the subway and intercity railway have been fully electrified. In the ship transport industry, electrification has also seen great progress in the past decade. The potential for electrification in the transport sector lies in electric vehicles, whether passenger cars or commercial vehicles, and China is already leading the world. Based on the characteristics of the vehicle, it has great uncertainty in the infrastructure requirements, and new challenges are also presented to the investment in infrastructure and the introduction of new generation technologies. ABB believes that electric mobility is a very promising industry. We are active participants and we are contributors. Through more than ten years of efforts, ABB now has a full range of charging and distribution solutions, and for some specific application scenarios, launched a high-power fast charging pile like 360kW to solve mileage anxiety. ABB has partnered with Oems on the electrification of heavy-duty trucks, helping them achieve electrification, and has developed a management platform for the electrification of commercial vehicle fleets. ABB also sponsored the ABB FIA Formula E World Championship, which received a very good response from all walks of life. We are very concerned about intelligent manufacturing and flexible production at the production end. The external production environment and the supplier environment are constantly changing, and then the flexible production can be maximized and the production efficiency can be maintained at all times. In the case of electric vehicles, by introducing flexible production, collaborative robots, mobile robots, and investing in high-speed networks and data connectivity, there is an opportunity to turn traditional production lines into artificial intelligence islands one by one. In this way, the entire production process can be very optimized, at any time to respond to the challenges of new external environment changes, through the support of big data, to achieve the entire production process at all times to ensure the optimal efficiency and improve competitiveness. The electricity consumption of the entire construction industry is very significant. In terms of electrification of the building industry, ABB has a very mature complete set of intelligent building management systems to achieve independent building management of lighting, comfort and safety. For the management system of building groups, more attention is paid to the introduction of the entire energy system, HVAC, refrigeration, water, power distribution and other integrated management systems. In the whole park, according to different application scenarios, from production park, business park, home park to hybrid park, according to the characteristics of the needs of the park, to provide the best optimization management platform to achieve the overall energy-saving effect. With the massive introduction of electrification, our demand for electricity will continue to grow. At this point, maximizing the introduction of renewable energy at the power generation end becomes critical. Only when renewable energy is applied at the power supply side can a green, recyclable and sustainable ecology be achieved. The introduction of renewable energy has some new challenges of its own, for the grid, whose power generation side is constantly changing due to weather; On the electricity side, with the movement of electric vehicles, a lot of uncertainty is created. So, the whole grid becomes a problem of control, is a smart grid, and digital technology has to be introduced. After the scale of electric vehicles, they should be considered as a mobile energy storage terminal, which can make a great contribution to the stability and efficiency of the smart grid. For the purpose of overall engineering thinking training, by adopting electromechanical modeling, motion control modeling and model-based development (MBD) of intelligent equipment commonly used in industry (AGV is the object of this competition), students’ “engineers” are trained in their overall abilities, including program planning and design, physical object modeling, control algorithm design, team collaboration, expression and presentation, etc. So as to achieve the purpose of training students’ engineering thinking and mastering methods and tools. With the accelerated development of new energy, the demand for photovoltaic industry is strong, and the use of robots in the production process of photovoltaic cell string modules has become an inevitable choice. The development of photovoltaic cell module robot typesetting system application software, combined with robots, will effectively achieve intelligent manufacturing process optimization and efficiency improvement. In the application scenario of photovoltaic cell string module intelligent manufacturing production line, participants will use simple and easy to use development tools to develop robot typesetting system application software; And on this basis, independent innovation, more application innovation functions of the robot system into this software, tap the potential of the robot in process optimization and efficiency improvement, insight into the opportunities in actual combat, and challenge problems in innovation. In actual maintenance, motor sweeping is often encountered, most of the time because the motor is lack of maintenance, and the bearing of the motor is not regularly checked and greased. The bearing of the motor is running at high speed for a long time because of the lack of oil, resulting in high temperature and damage to the bearing, which then causes the motor to be swept, thus damaging the motor.

ABB DSDX404 automation processor module

ABB CP430T-ETHABB SNAT617CHC

ABB SPA-ZC22

ABB SPAD346C

ABB SPCJ4D34-AA

ABB TA524

ABB TB521-ETH

ABB TC625

ABB TC630

ABB TET106 11355-0-6050000

ABB TK516

ABB TU515

ABB TU804-1

ABB TU810V1

ABB XI16E1

ABB XM06B5

ABB XO16N1-B20 XO16N1-C3.0

ABB YB560100-EA S3

ABB YYT107A

ABB 07KT97H3

ABB 086329-003

ABB 086329-004

ABB 086345-504

ABB 086351-004

ABB 12KM02E-V0002

ABB 3BHB003154R0101

ABB 3BHB004027R0101

ABB 3BHE039203R0101

ABB 3HAB8101-19 DSQC545A

ABB 3HAB8859-1/03A