ABB DSAI146 automation processor module

Brand ABB color Standard Application Industrial height 317mm rated current 545mA

Protection Level IP45 Suitable for motor power 325KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part Number DSAI146

Applicable pipe 2 Whether imported is weighing 4.22 kg can be sold nationwide

ABB DSAI146 automation processor module

Hardware: The main control device is composed of DSQC1000 main computer and other core hardware. The single-cabinet IRC5 is equipped with the DSQC1000 main computer, which is the brain of the whole controller, which is used to receive the robot motion data and peripheral signals, and send the signals to each unit. The axis computer receives the position data returned by the serial measuring board of the robot axis, compares and calculates with the original position data and outputs the new position and speed control parameters. The main servo driver is used to drive the servo motors distributed on the 6 axes of the robot; The I/O module is used to connect external signals, which is a user-defined input and output signal board. The safety panel is used to connect the safety-related signals, and the LED lights remain on during normal operation.

Software: Generally consists of an operating system and a library of algorithms. The operating system mainly includes VxWor (embedded real-time operating system) and the open source operating system Windows CE, embedded Linux, embedded Linux, μC/OS-Ⅱ and the general ROS platform. The algorithm library includes the underlying algorithm library and the applied process algorithm library. The underlying algorithm library is an algorithm developed directly on the computer operating system. The control algorithm is used to plan the moving point of the robot, and the dynamic algorithm is used to identify the moment of inertia of the body load. Application process algorithm library is an algorithm developed by software users. RobotWare is a family of embedded industrial robot controller software designed to control a wide range of industrial robots produced by ABB. Optional add-ons are included to provide robot users with a range of rich system functions, such as multi-tasking, document information transfer to the robot, external system communication, advanced motion tasks, etc.

ABB also offers a variety of software packages for different functions in different application scenarios. Including spraying software package, loading and unloading software package, picking software package, machining software package, cutting software package, palletizing software package, PickMaster package and so on. Customized software services are provided for welding, cutting, picking, palletizing and other specialized links to improve the efficiency of specific production links.

In addition, the programming methods of industrial robots generally include teaching programming and virtual simulation programming. Teaching programming requires the operator to guide the robot step by step and inform the robot of the actions to be completed through the operation of the teaching device. After the teaching operation is completed, the program is generated, and the robot can repeat all the teaching actions according to the generated program, which is suitable for repeated operation robots such as automatic production lines. Virtual simulation programming is to realize the two functions of programming and simulation through programming software, which can not only write programs, but also simulate the robot movement to verify the effectiveness of the program. Virtual simulation programming requires specific programming software from Robot manufacturers, such as ABB’s Robot Studio. Robot Studio is ABB’s robot simulation and programming software. On the one hand, it provides a visual programming environment to make robot programming more flexible and efficient. On the other hand, powerful simulation functions can help users develop and test robot applications. In January 2023, ABB enhanced its RobotStudio robot programming and simulation software with Cloud capabilities, with the new RobotStudio Cloud enabling individuals and teams to collaborate on robot unit design remotely and in real time on any device.

IT Architecture: The role of software is expected to gradually increase. We believe that with the development of industrial robots to intelligence, IT has gradually entered the software-defined stage, and the robot is no longer a mechanical product (iterative slow/soft and hard highly coupled), and gradually evolved into an IT product (iterative fast/soft and hard decoupling). Whether it is the operating system, the algorithm library, or the programming and development software, it is playing an increasingly important role in the robot iteration process, and the difference of software algorithms will have an important impact on the intelligence level that the robot can finally achieve. Based on this, we are optimistic about the development opportunities of IT software under the transformation of the robot industry, and the status of software is expected to gradually improve.

ABB DSAI146 automation processor module

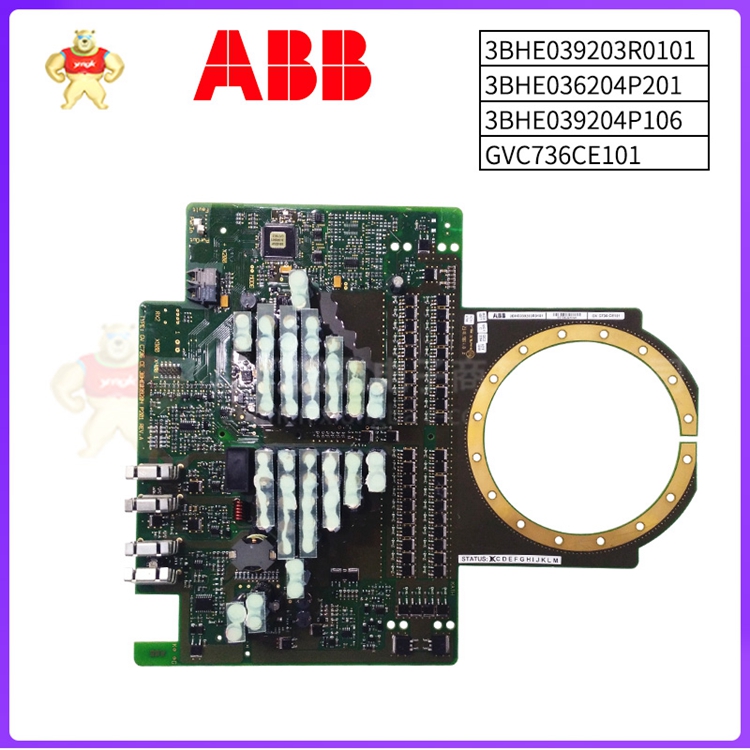

ABB UFC092BE01

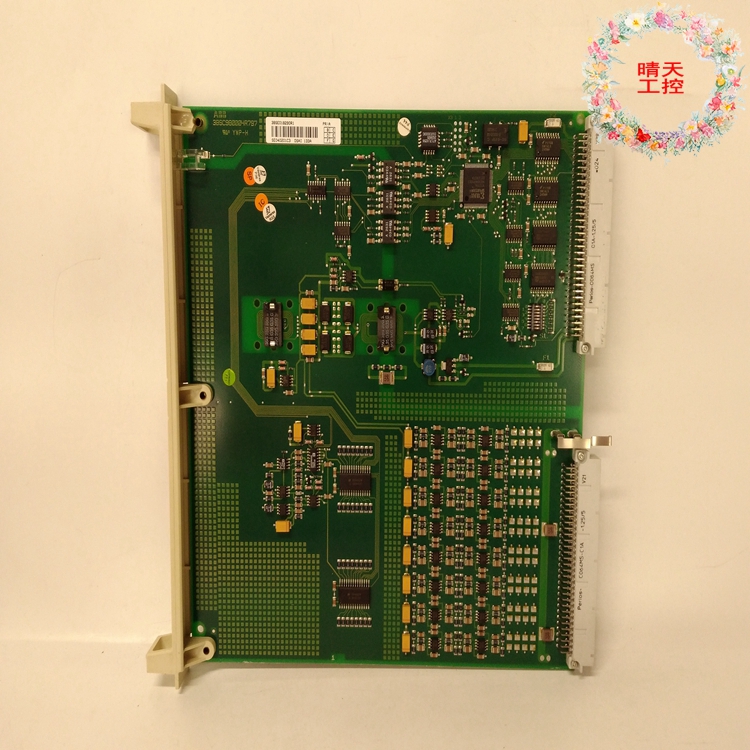

ABB UFC718AE01

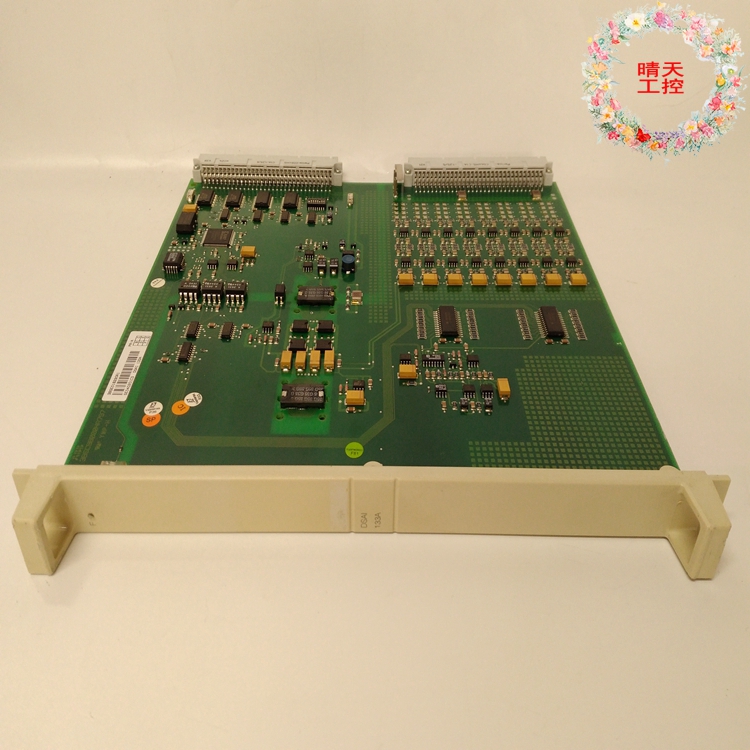

ABB UNS0119A-P V101

ABB UNS0874A

ABB UNS2980c-ZV4

ABB V4550220-0100

ABB 504994880

ABB 0745648E

ABB 0745745Q

ABB 07AC91D

ABB 07BR61R1 GJV3074376R1

ABB 07CR41

ABB 07DC91C

ABB 07EA90-SI

ABB 07KR51 220VDC

ABB 086339-001

ABB 086349-002

ABB 086406-002

ABB 086407-502

ABB 128877-103

ABB 1TGB302003R0003

ABB 1TGE120011R1001

ABB 216AB61

ABB 216DB61

ABB 216DB61 HESG324063R100/J

ABB 216EA61b

ABB 216EA62 1MRB150083R1/F 1MRB178066R1/F

ABB 216GD61A HESG324436R3/A HESG324428