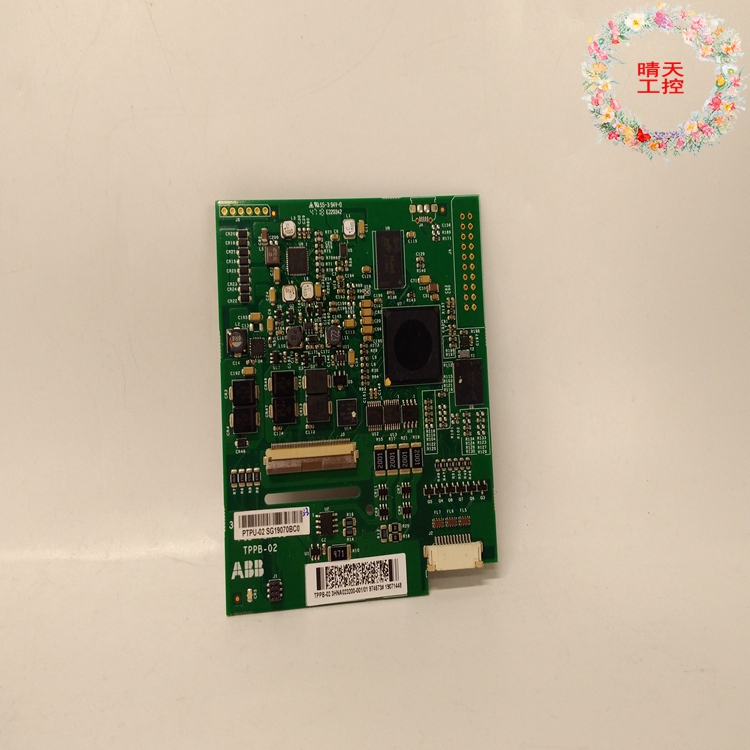

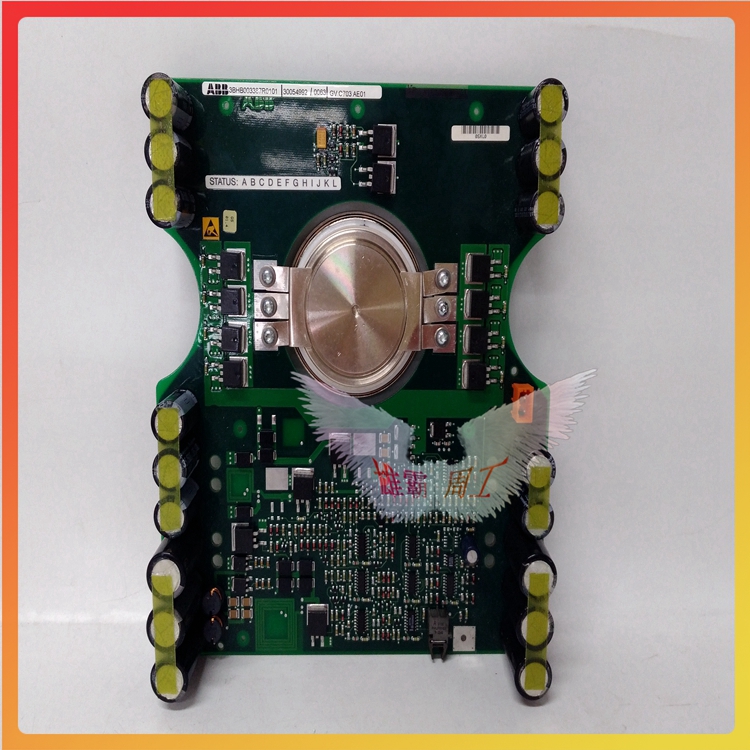

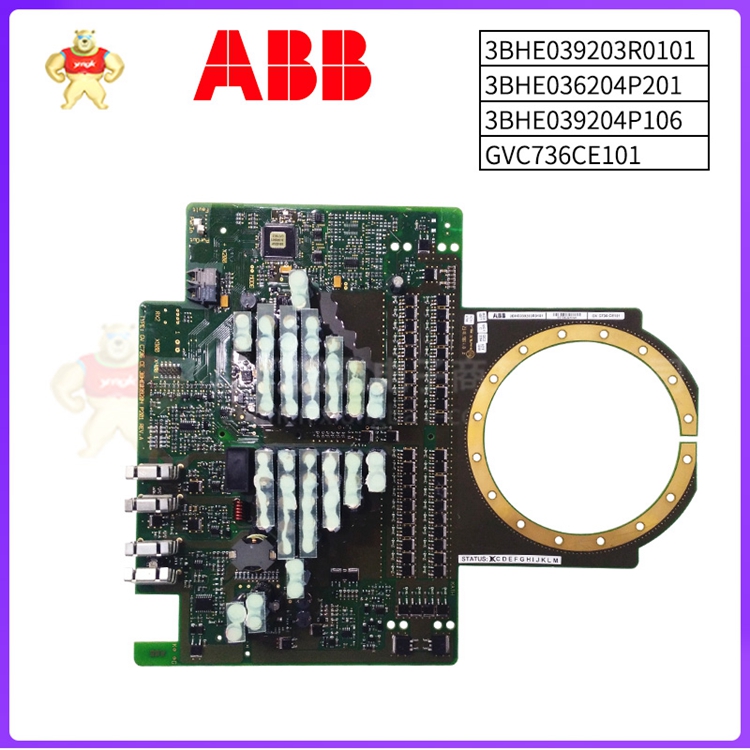

ABB drive unit 3HAB8101-8/08Y rectifier module

Brand ABB Color Standard Application Industrial height 525mm rated current 360mA

Protection level IP45 Suitable for motor power 86KW Application Site Power Industry BOM Number GJR2391500R1220 Power industry HIEE401782R0001 Part number 3HAB8101-8/08Y

Applicable pipe 2 Whether imported is weighing 5.18 kg can be sold nationwide

ABB drive unit 3HAB8101-8/08Y rectifier module

Driving this evolution in Supply Chain 4.0 are major advances in automation and traceability technology. For example, RFID scanning technology updates traditional 2D barcodes and increases productivity, while being integrated with other solutions such as machine vision and predictive analytics. Fixed RFID readers will play an important role in the future warehouse environment. When combined with other advanced solutions, RFID technology can support key economic drivers in a warehouse or distribution center, including asset visibility, productivity, quality control, and tracking and traceability.

RFID technology is becoming more effective and cost-effective in warehouse and logistics environments, leading to wider adoption. However, to achieve (ROI), you need to work with solution providers to help integrate technology into the business to avoid siloed workflows and minimize complexity. Manufacturing plants are particularly suitable for passive RFID readers because materials there typically follow a fixed path through the facility. The new wide-area advanced RFID antenna expands the scanning range for real-time location tracking of every asset in the warehouse.

In discrete manufacturing, inventory is often serialized and each unique part has a dedicated location. Using RFID tags, production managers are able to ensure that materials are properly sequenced so that the right components enter the production line at the right time.

Increased visibility not only enables organizations to detect errors after they occur, it also helps nip them in the head, prevent problems from occurring, and avoid potential quality control issues that could damage a company’s reputation or profitability. In addition, preventing asset utilization problems and improving the tracking of raw materials can help companies maintain production lines without affecting productivity. Supply chain transformation is not limited to one or a few industries. Much of the same supply chain technology can be applied to multiple industries – from automotive and apparel to pharmaceuticals and groceries, from manufacturing plants and warehouses to transportation to final distribution points, such as retail stores and medical facilities. RFID solutions can help grocery stores, fast food restaurants, food suppliers, and even hospitals significantly improve inventory visibility, reduce costs, and reduce waste. Installing passive RFID readers in passageways such as porches or coolers can improve control and visibility without increasing labor costs. RFID also improves traceability in the pharmaceutical supply chain and integrates with temperature monitoring solutions to provide more detailed information.

The frequency can be gradually increased by running under scalar first to observe whether the current fluctuation is large. Storage requirement

The requirements for storage of spare modules are as follows: All modules must be stored in anti-static bags or according to the requirements of the manufacturer, and the temperature and humidity of the module storage room should also meet the requirements of the manufacturer; When accessing the module, anti-static measures should be taken, it is forbidden to touch the circuit board by hand at any time, and it should be registered and handled in and out of the warehouse.

ABB drive unit 3HAB8101-8/08Y rectifier module

ABB CI868K01-eA

ABB CP430T-ETH

ABB D2D146-AA28-28

ABB DAI03

ABB DAO01

ABB DDI01

ABB DDO01

ABB DLM02

ABB DSAI133A

ABB DSDO115A

ABB DSDX453

ABB DSPC454

ABB DSQC332A

ABB DSQC504

ABB DSQC509

ABB DSQC633

ABB DSRF197K01

ABB DTCC901B

ABB DTDX991A

ABB FPX86-9329–C

ABB GCC960C102

ABB GCC960C103

ABB GDC801B101

ABB HAC319AEV1