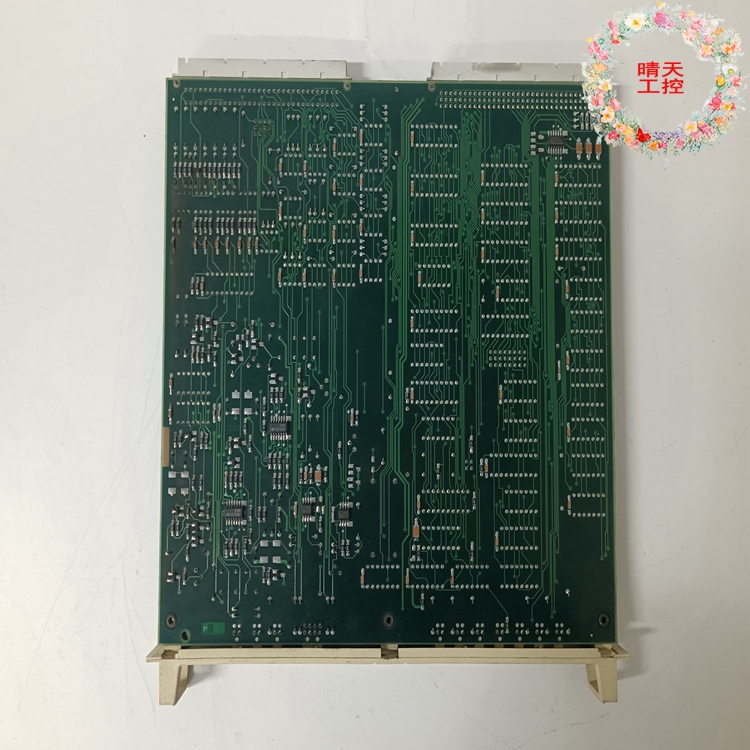

ABB distributed control system DSBB175 automation controller DCS spare parts

Brand ABB color standard Application Industrial height 387mm rated current 265mA

Protection Level IP45 Suitable for motor power 325KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part Number DSBB175

Applicable pipe 2 Whether imported is weighing 4.22 kg can be sold nationwide

ABB distributed control system DSBB175 automation controller DCS spare parts

PLC system; EMERSON’s original Fisher-Rosemount DeltaV system; ABB’s Infi90, Freelance2000, Industrial IT (AC800F); Honeywell TDC3000, TPS; Foxboro’s I/A Series, etc.; The domestic DCS are Hollysys HS1000, HS2000, MACS, MACS SmartPro (FCS). With the rapid development of fieldbus technology, in particular, the China Bus Standards Committee approved Profibus-DP as China’s industry design standard in 2002, and ProfiNet as China’s bus standard in November 2006, which provides the technical basis and design standard basis for the popularization and promotion of bus technology in China. It will greatly promote the application of Chinese control system on the bus, and also improve the reliability and data interchangeability of the system. At the same time, it also provides a bus standard for the bus interface of other electrical automation products in China, which is conducive to the mutual communication of the bus of the product and improves the intelligence of the electrical automation products. At present, the domestic electrical automation products rarely have a bus communication interface, and technological progress in this area should be strengthened. At the same time, some automation companies based on their own DCS system, developed for the glass production requirements of the control system software, do well Siemens PCS7 system, specially developed integrated in the PCS7 glass control, analysis, diagnosis software, making PCS7 in the global glass production line to be widely used. At present, as far as the mathematical model and simulation optimization control software of glass process engineering are concerned, especially the expert control software of glass melting kiln, the control experts at home and abroad are actively developing. Glass melting kiln is not only a key part of glass production, but also the most energy consuming part. Through the application of expert control software, it is of great significance to improve the melting rate of kiln, improve the quality of glass, prolong the melting order, reduce energy consumption and reduce the emission of sulfur dioxide. To achieve the best combustion control is a goal that manufacturers pursue in the hot end control with the help of advanced DCS system, which not only has good economic benefits, but also has huge social benefits. In this regard, some foreign manufacturers started early and did a better job. Such as GS company in the Czech Republic, TNO Glass Group in the Netherlands, UAS company in Germany, STG Company, etc. They have been successfully applied in float production lines abroad. The ESⅢ expert control of GS company in Czech Republic has been successfully applied in an electronic glass production line of Lobo Group, and the control effect is remarkable. At present, domestic manufacturers have recognized the benefits of this aspect, and many manufacturers have begun to explore the application of this aspect. This is a very good start. In the future, the glass manufacturers will change from the current focus on hardware equipment to both hardware and software. (2) Electric heating: electric heating is required on the tin tank and annealing kiln, which requires the use of electric heating controllers, dry transformers and heating elements. At present, under the requirements of high reliability and high precision, the power regulator products used are mostly Thyro-P or Thyro-A products of German AEG Power System company. AEG power regulator has been successfully used and verified in many float glass wires in China, and has won wide praise for its good and unique control characteristics, high reliability and high precision. With the establishment of the wholly-owned enterprise – Hao Shang (Beijing) Power System Co., Ltd. in China on June 12, 2006, it is fully responsible for the sales, service, technical support, training, maintenance and other businesses of AEG power system in Germany, which will surely lay a good foundation for the rapid growth of the company’s business in China. There are many domestic power regulator products, good and bad, the best is the power regulator of Sichuan Yingjie Company, other power regulator product technology and reliability need to be improved. It is worth mentioning that some float glass manufacturers in order to cheap, blindly use low quality power regulator products, and sometimes the unreliability of the power regulator causes the quality of the product to be affected, which can be said to be more than worth the loss. Be sure to choose cost-effective products! At present, the shortcomings of domestic power regulator products are easy to breakdown, low precision, poor reliability, no bus communication. In general, dry transformers are not satisfactory, mainly reflected in low accuracy, high magnetic flux, more harmonics, large volume and so on. (3) Automatic edge drawing machine. This equipment has been realized in China, there are two or three manufacturers can quantify the production, its control accuracy and equipment stability than the initial has been greatly improved. For example, Lobo Group Sike Glass automatic control equipment Co., Ltd. production of fully automatic suspension automatic edge machine has been equipped with a number of domestic high-grade float glass and electronic glass production lines and achieved export. It adopts domestic processing of mechanical parts, and the control system mainly adopts Siemens PLC and TP touch screen for fully automatic control, and the automation degree and control accuracy of the whole machine can completely replace the imported products. The use of automatic edge drawing machine greatly improves the production efficiency of glass forming section, improves the quality of glass and production stability. This is particularly obvious in the large tonnage float glass production line. (4) tin stirring device and skimming machine.

ABB distributed control system DSBB175 automation controller DCS spare parts

ABB 5SHY3545L0005

ABB 5SHY35L4510

ABB 5SHY35L4520

ABB AI845

ABB AI880-1

ABB AO845A

ABB AO845A-eA

ABB ARC093AV1

ABB ARCOL 0338

ABB ARCOL 0339

ABB D2D146-AA28-28

ABB DAI03

ABB DAO01

ABB DDI01

ABB DDO01

ABB DLM02

ABB DSAI133A

ABB DSDO115A

ABB DSDX453

ABB DSPC454

ABB DSQC332A

ABB DSQC504

ABB DSQC509

ABB DSQC633

ABB DSRF197K01

ABB DTCC901B

ABB DTDX991A

ABB FPX86-9329–C

ABB GCC960C102

ABB GCC960C103

ABB GDC801B101

ABB HAC319AEV1

ABB ICSI16E1

ABB IMASI23

ABB IMBLK01

ABB IMDS014

ABB IMDSI14

ABB IMDSM04

ABB IMFECI2

ABB INIIT03

ABB INIIT13

ABB INIT03

ABB INNIS21

ABB INNPM12

ABB KUC720AE

ABB KUC720AE01

ABB MSR04X1

ABB MVR 0.44-10KA

ABB NPCT-01C

ABB PCD244A101

ABB PDD200A101