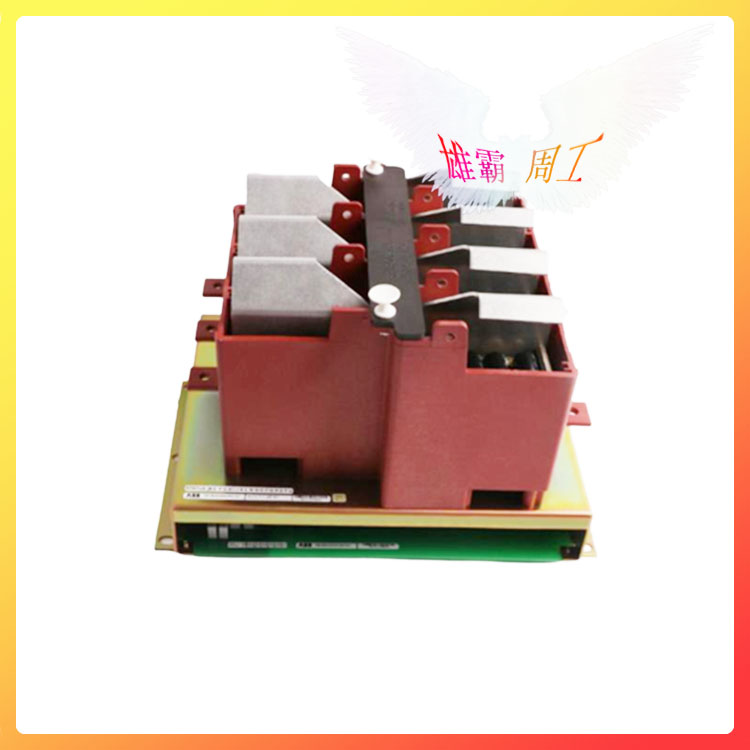

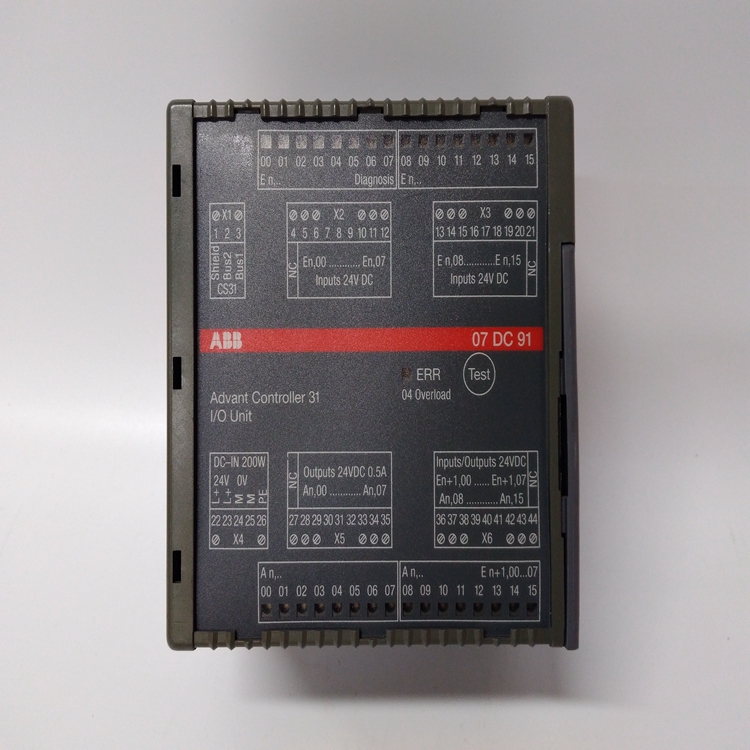

ABB communication interface module CI520V1

Brand ABB Color Standard Application Industrial height 375mm rated current 478mA

Protection Level IP45 Suitable for motor power 116KW Application Site Power Industry BOM Number GJR2391500R1220 Power industry HIEE401782R0001 Part Number CI520V1

Applicable pipe 2 Whether imported is weighing 6.88 kg can be sold nationwide

ABB communication interface module CI520V1

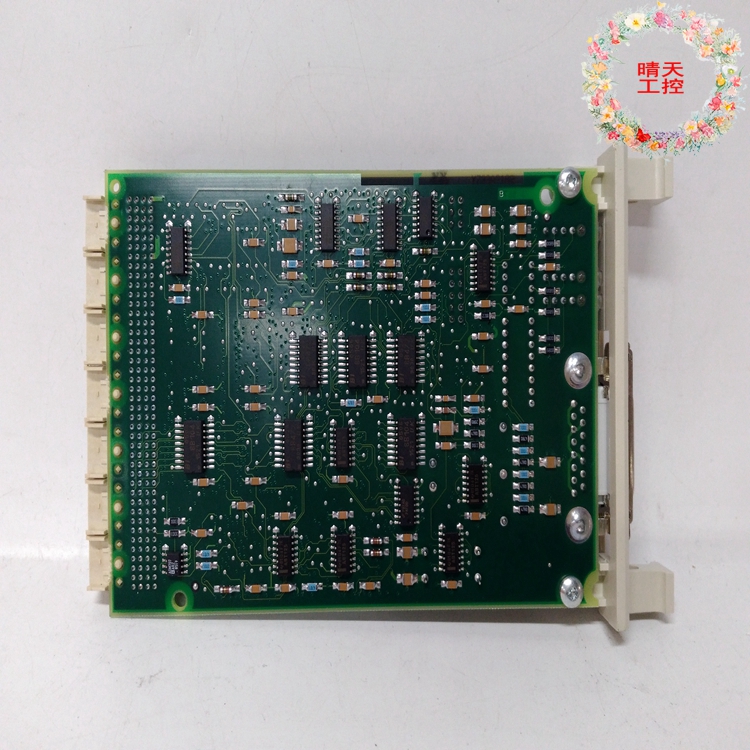

ABB CI615 CI610 CI520V1 BRC300 PLC Extension or function in ladder logic

Pc-based motion can also be integrated with PC-based logic control and HMI software, often running on the same platform, to enable integrated “single box” control of the machine. But PC-based motion is also expensive and has issues with ease of use and maintenance – motion control code is often written in proprietary or complex programming languages. Some PC-based controllers are nothing more than standalone controllers installed inside a PC. These motion control “cards” use a PC bus for communication and power, but they are still proprietary controllers with dedicated DSPS and other motion-specific circuits. The third type, PLC-based control, is often considered the simplest way to control motion. The classical “pulse and direction” signals widely used by PLCS provide a cheap, noise-free (digital) method for precision motion control.

Extensions or functional blocks in PLC ladder logic are typically used for programming and are easy for plant personnel to understand and maintain. Although typically limited to a few control axes and with limited coordination between axes, PLC controllers with pulse and direction capabilities are well suited for many motion applications. Typically, low-cost PLCS are already used for logic control of machines, and can also handle motion tasks by adding pulse output cards and some additional programming, eliminating the need to integrate the motion controller with a separate logic controller. Machine manufacturers can also save a lot of time when implementing PLC-based systems, especially if they are already familiar with PLCS and their programming software. In a typical PLC-based motion control system, the PLC uses a high-speed pulse output card to generate a “pulse train” for each servo or stepper driver. The driver receives the pulses and adjusts the motor shaft according to the preset amount of each pulse.

-1.jpg)

ABB communication interface module CI520V1

ABB IMDSI14

ABB IMDSM04

ABB IMFECI2

ABB INIIT03

ABB INIIT13

ABB INIT03

ABB INNIS21

ABB INNPM12

ABB KUC720AE

ABB KUC720AE01

ABB MSR04X1

ABB MVR 0.44-10KA

ABB NPCT-01C

ABB PCD244A101

ABB PDD200A101

ABB PDD205A0121

ABB PFCL201C 10KN

ABB PFCL201C 20KN

ABB PFTL101A 1.0KN

ABB PFXA401SF

ABB PM864AK01-eA

ABB PM866A-2

ABB PU515A

ABB REF610

ABB RET650

ABB RK682011-BA

ABB SA801F

ABB SAFT183VMC

ABB SC510

ABB SK616001-A

-1.jpg)

-1-100x100.jpg)

-1-100x100.jpg)