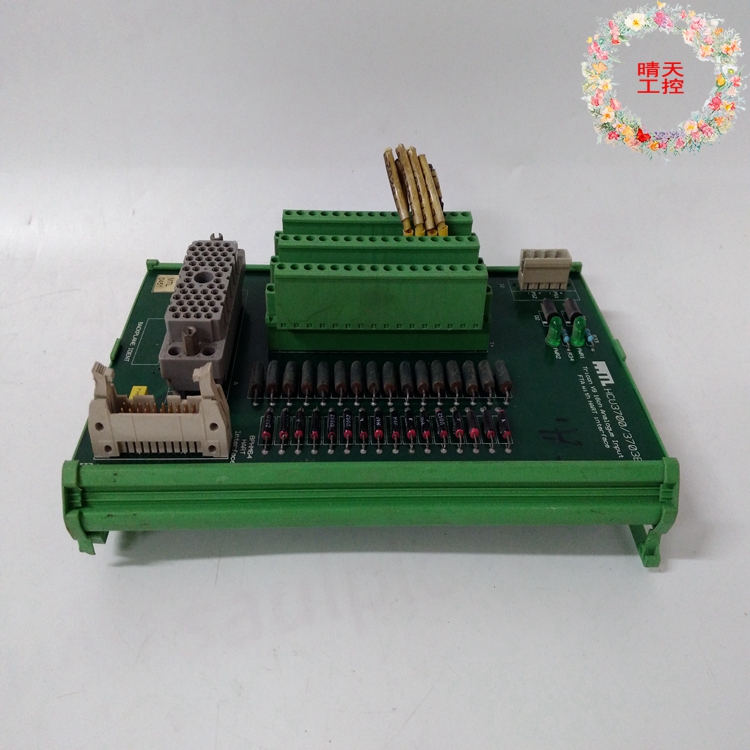

Triconex Invensys 2481 Base control equipment for industrial spare parts applications

The brand TRICONEX color standard applies industrial height 250mm rated current 396mA

Protection Level IP45 Suitable for motor power 159KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part No. 2481

Applicable pipe 2 Whether imported is weighing 3.17 kg can be sold nationwide

![]()

Triconex Invensys 2481 Base control equipment for industrial spare parts applications

TRICONEX 2481 users report a 35-40 minute reduction in lockout/listing (LOTO) process time. This touch-safe compact PESD features voltmeter-compatible test points and redundant LED voltage presence indications rated up to 1000 vac/VDC. ChekVolt is quickly installed via a 30mm stripper and includes four wires encapsulated in the structure, making LOTO safer, smarter and more efficient even in the harshest environments.

Technology partner Festo has introduced new innovative technology for Rockwell Automation programmable logic controllers (PLCS) that seamlessly captures data from Festo pneumatic valves and actuators. These solutions help Oems, system integrators and end users reduce costs, reduce time to market and improve operational performance.

The TRICONEX 2481 factory talks to Rockwell Automation’s Edge Gateway (FTEG) to connect the OT to it. The FTEG tool scans Ethernet /IP networks to discover devices. With the Festo CPX-FB36 bus node now approved by FTEG, basic diagnostic information from intelligent pneumatic devices such as Festo valve terminals and energy saving pneumatic devices is easily accessible.

Through its association with FTEG, Festo became one of the first third-party vendors to support FTEG and seamlessly incorporate digital pneumatic information under the Rockwell Automation IIoT umbrella.

Rockwell Automation is also showcasing a number of new innovations, one of which is the new FlexHA 5000 I/O platform designed specifically for process applications, with full five-nine redundancy right out of the box. But perhaps more importantly, the FlexHA platform includes fully software-configurable I/O.

TRICONEX 2481 The platform’s fully software-configurable I/O allows users, EPCs, and system integrators to know the approximate total number of I/ OS required, rather than the exact details required. This means they can separate the hardware and software design processes when designing a project – ordering the hardware earlier while completing the final software development work. This speeds up the design of automated systems, resulting in faster delivery of value.

Triconex Invensys 2481 Base control equipment for industrial spare parts applications

TRICONEX 4000094-310

TRICONEX 4000103-510

TRICONEX 4000103-510N

TRICONEX 4000163-510

TRICONEX 4000164-520

TRICONEX 4101

TRICONEX 4107

TRICONEX 4118

TRICONEX 4119

TRICONEX 4119A

TRICONEX 4210

TRICONEX 4211

TRICONEX 4328

TRICONEX 4329

TRICONEX 4351B

TRICONEX 4352AN

TRICONEX 4352B

TRICONEX 4400

TRICONEX 4500

TRICONEX 4507

TRICONEX 4508

TRICONEX 4609

TRICONEX 7400206-100

TRICONEX 7400212-100

.jpg)

.jpg)

.jpg)