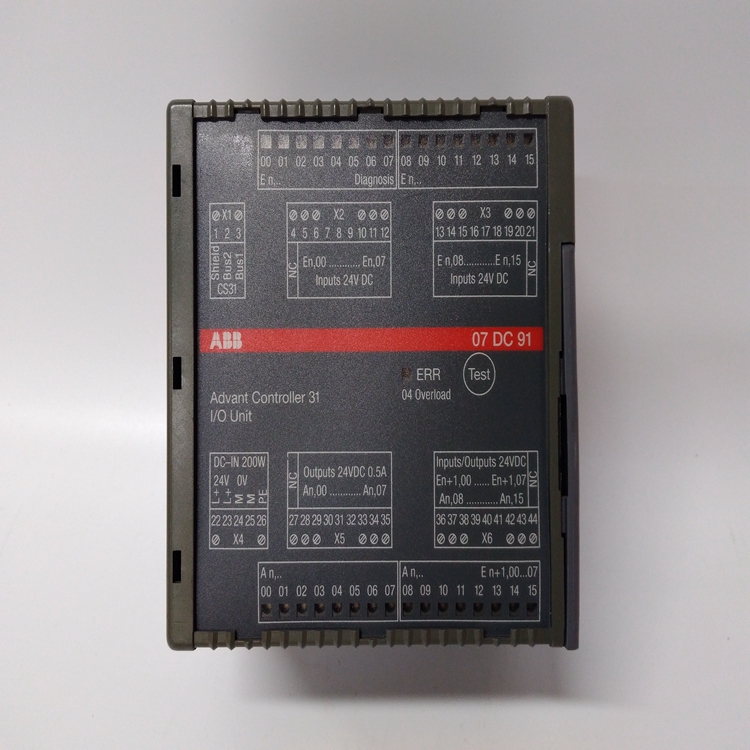

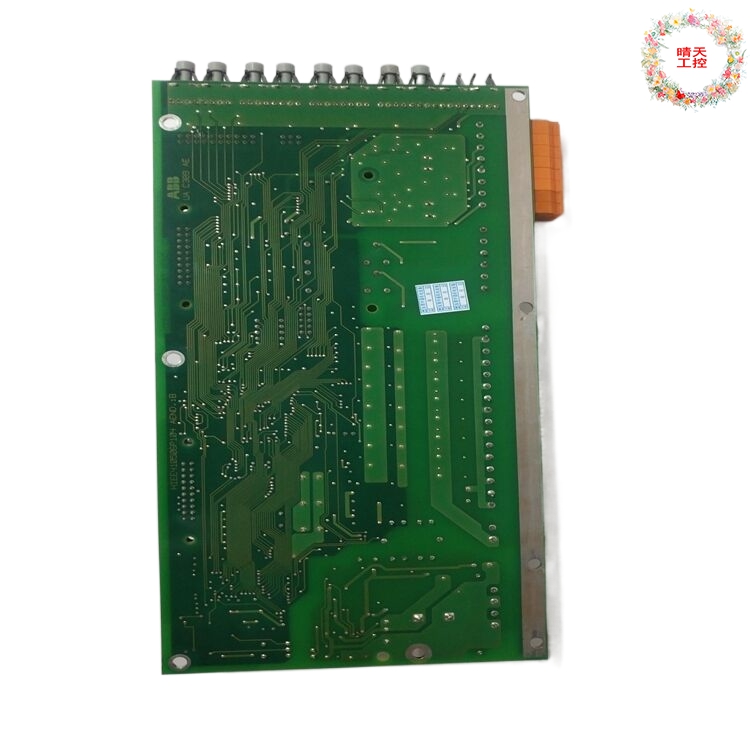

ABB controller HIEE300890R0001 UAC383AE01 PCB board automation

Brand ABB height 28mm rated current 220mA

Protection level adapted to motor power Applicable site Material code

IP45 28KW Power industry HIEE401782R0001

Part number UAC383AE01 HIEE300890R0001

Applicable pipe whether imported is weighing 1.7 kg can be sold nationwide

ABB controller HIEE300890R0001 UAC383AE01 PCB board automation

The controller is the core component of DCS, which is equivalent to a PC. Some Das controllers are PCS themselves. It mainly has CPU, RAM, F2PROM and ROM chips, as well as two interfaces, one downward to receive the signal from the I/O bus, the other interface is to send the signal to the network to connect with the human-machine interface. ROM is used to store control algorithms that complete various computing functions (some Das are called functional block libraries). In the library store functional blocks, such as control algorithm PID, PID with dead zone, integral separation PID arithmetic operation addition, subtraction, multiplication, division, square, square root, function operation once filter, sine, cosine, X-Y function generator, lead-lag; More advanced algorithms include Smith estimation, C language interface, matrix addition, matrix multiplication; Logical operations include logic and, logic or, logic not, logic and not, etc. The station function block is usually used not only to combine the analog quantity and the switch quantity, but also to associate with people. The more functional blocks, the easier it is for users to write applications (i.e., configure them). According to the process requirements, the function blocks are connected to form a control scheme. The control scheme is stored in E2PROM. Because E2PROM can be erased, the configuration changes with the process, so the configuration is stored in E2PROM. Different users have different configurations. During configuration, the user selects the desired function block from the function block library, fills in the parameters, and connects the function block. The control scheme is formed and stored in E2PROM. At this time, the controller becomes the operating mode after the configuration mode is put into operation, and the operating system, function block configuration software and communication software are installed in the controller. For the safe operation of the system, the closed-loop controller must be redundant, one in use, and hot standby.

The communication network connects the process station and the man-machine interface into a system. UAC383AE01 HIEE300890R0001 Communication network has several different structural forms, such as bus, ring and star. Bus lines are also logically circular. The star type is only suitable for small systems. Whether it is ring type or bus type, it is generally used in broadcast. Other protocols have been used less frequently. The speed of the communication network is around 10M and 100Mb/s.

Closed-loop controllers, analog data collectors and logic operators can be directly connected to the human-machine interface on the communication network, and each different controller on the network is an independent node on the network. Each node performs a different function. They should all have network interfaces. Some DOS in order to save the network interface, all the process control equipment, that is, closed-loop controller, analog data collector and logic arithmetic device, is connected to the control bus in advance, called the process control station. This can increase the number of LO points that can be received by the process control station and save the interface. Then it is connected to the network through the interface and connected to the human-machine interface.

There are four different types of nodes in HMI, they are operation station, engineer workstation, historical trend station and dynamic data server. The operating station is equipped with the operating system, monitoring software and controller driver software, displaying the system label, dynamic flow chart and alarm information. A Das system can have several operating stations, each operating station can display the same content, or it can be different content. DOS manufacturers can be equipped with special operating stations or general operating stations. The engineer workstation configures the controller (CAD) and can also configure the operation station (as a dynamic flow chart). If the mapping ability of the monitoring software is strong, the mapping work can be completed by the monitoring software independently. Another function of the engineer station is to read the configuration of the controller, which is used to upgrade the controller and find faults. We call it the reverse Engineer Station. The historical trend station stores historical data. The dynamic data server is the interface between Das and MIS, and also the isolation between Das and Web.

ABB controller HIEE300890R0001 UAC383AE01 PCB board automation

ABB ARC093AV1

ABB ARCOL 0338

ABB ARCOL 0339

ABB ARCOL 0346

ABB BC25

ABB BRC300

ABB C310/0020/STD

ABB CI868K01-eA

ABB CP430T-ETH

ABB D2D146-AA28-28

ABB DAI03

ABB DAO01

ABB DDI01

ABB DDO01

ABB DLM02

ABB DSAI133A

ABB DSDO115A

ABB DSDX453

ABB DSPC454

ABB DSQC332A

ABB DSQC504

ABB DSQC509

ABB DSQC633

ABB DSRF197K01