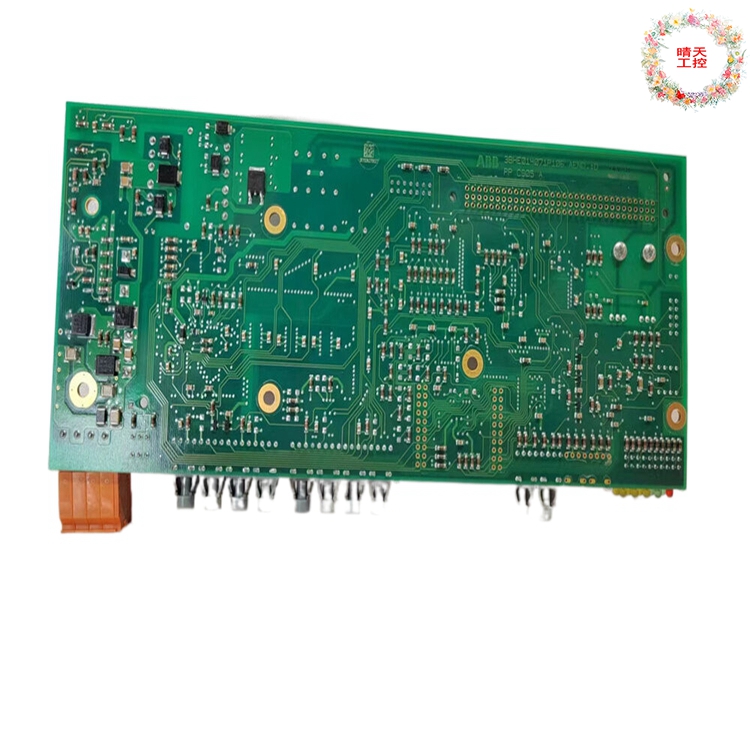

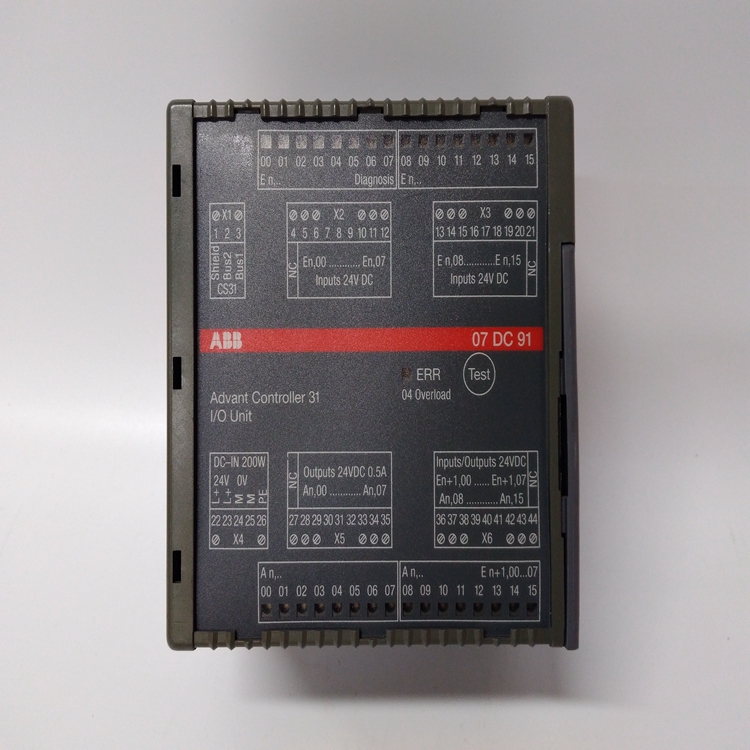

ABB PPC905AE101 3BHE014070R0101 Control module

Brand ABB height 28mm rated current 150mA

Protection level adapted to motor power Applicable site Material code

IP45 28KW Power industry HIEE401782R0001

Part number PPC905AE101 3BHE014070R0101

Applicable pipe whether imported is weighing 1.7 kg can be sold nationwide

ABB PPC905AE101 3BHE014070R0101 Control module

Foxbore (Foxboro) : I/A Series system, FBM full range (field input/output modules)

Sequence control, ladder logic control, accident recall processing, digital to analog conversion, input/output signal processing, data communication and processing, etc.

Vestinghouse: 1C31 series DCS system, CPU, OVATI0N system, WDPF system, WEStation system spare parts.

Triconex (Invensys) : Redundant fault tolerant control system, the most modern fault tolerant controller based on triple module redundancy (TMR) architecture.

EMERSON: Modules, cards, drives and other spare parts.

XYCOM: XVME series

Bently (Bentley) : 3500/3300 system.

Rockwell: ICS Systems. ;

ABB: PM full series DCS system, ICT high voltage inverter series, industrial robot spare parts DSQC series, INFI 90 and so on.

Bailey: BRC series DCS system, etc.

Allen-Bradley: 1756, 1785, 1771, 1746 full series system, etc.

Yokogawa: CP series, etc.

Honeywell (Honeywell) : TK/TC/CC systems, etc.

Reliance (Ryan) : 57C series, etc.

Schneider: 140 series processors, control cards, power modules, etc.

Modicon: AS series PLC system spare parts.

Siemens (Siemens) : 6 es5 / es7414/6 es7415 / es7416 series PLC system spare parts,

Siemens MOORE, Siemens Simatie C1, Siemens numerical control system, etc.

Motorola: MVME 162, MVME 167, MYVME1772, MVME177 and other series.

XYCOM: I/0, VmeE board and processor, etc.

GE (General Electric) : IC698/IC697 full series of PLC systems, modules, cards, drivers and other spare parts.

Yaskawa: Servo controller, servo motor, servo driver.

Bosch Rexroth (Bosch Rexroth) : Indramat, I/O module, motor, PLC controller, drive module, etc.

Woodward: SPC valve position controller, PEAK150 digital controller.

ABB crane control designer NTK addresses these issues by providing the best safety system for tower cranes – the company’s unique crane cab with a round or oval cab window is easy to identify. NTK is now installing a control system based on ABB Security PLC. The system continuously monitors load torque and operating and collision zones in real time – up to SIL3 (IEC 61508 and 62061) PLe (ISO 13849-1) functional safety levels. It provides immediate and up-to-date visibility to the operator of all critical crane status indicators. The moving speed of the crane is now also controlled by a fully dynamic calculation of the load torque.

The use of a safety PLC – ABB’s AC500-S – simplifies this control upgrade project due to its built-in mathematical capabilities. Unlike other safety controller options, the PLC supports trigonometric mathematical functions, which greatly speeds up static and dynamic crane load safety calculations. The position of the trolley, the radius of the crane, and the load and wind conditions are displayed through NTK’s graphical touch screen user interface.

“Safety PLCS perform complex safety algorithm functions to monitor critical parameters. Among other things, it ensures that the allowable load moment is never exceeded to prevent the crane from tipping over over overload, “says Ralf Tensing, founder of NTK Ingenieurburo. “Status is now displayed in real time. The operator can see at a glance where the trolley or crane is and what the load is. It’s a huge *** when you’re working in crowded venues or at high altitudes.”

NTK has always been at the forefront of crane control safety. For this iteration of its control system, NTK agreed to be one of ABB’s first test houses to upgrade the control system to a dual PLC architecture of the AC500-S safety PLC with new mathematical capabilities. This allows NTK to use the new security PLC early in the development cycle. In return, the NTK developers provided ABB with feedback on the PLC and its development tools.

NTK’s new control system took about 12 months in total to bring to market. However, this included a period when it did its own pre-release with a crane OEM customer – who provided NTK with their feedback on the new safety control system. The new security code itself was developed in a relatively short period of about three months – thanks in large part to the quality of ABB’s programming tools.

AC500-S offers the most secure certified structured text programming language instead of using the most secure PLC functional blocks for programming. This high-level language includes the ability to use complex structures such as IF statements, giving NTK greater flexibility to develop its unique crane safety monitoring and user interface concepts. In addition, one of the key development tools that helped NTK transition from writing “standard” PLC control code to generating secure PLC code was the availability of ABB’s unique Secure Code Analyzer (SCA). The tool verifies that the user is following safe programming rules or guidelines according to IEC 61508-3. When NTK creates new software modules, these can be quickly verified by SCA tools,

Another important part of the overall NTK development environment is ABB’s Automation Builder tool suite. This provides

ABB PPC905AE101 3BHE014070R0101 Control module

ABB 5SDD1060F0001

ABB 5SDF0860H0003

ABB 5SGY3545L0003

ABB 5SGY3545L0017

ABB 5SHX06F6004

ABB 5SHX1060H0003

ABB 5SHX10H6004

ABB 5SHX14H4502

ABB 5SHY3545L0003

ABB 5SHY3545L0005

ABB 5SHY35L4510

ABB 5SHY35L4520

ABB AI845

ABB AI880-1

ABB AO845A

ABB AO845A-eA